HOW TO CLEAN

and PRESS COMIC BOOKS

WHAT IS COMIC

BOOK PRESSING?

Comic book pressing is the process of flattening out a comic

book that has been wrinkled or damaged. Comics can get bent

during shipping or have creaselines from heavy reading. Good

news: Comic Books can be pressed using a t-shirt heatpress

machine, a book press, a stack of short boxes, or anything

heavy and flat. The idea is simple: to smooth out the waves

and bumps on the cover of a comic book. This makes the overall

grade and eye appeal of the book increase considerably. Comic

book pressing is not restoration, more like comic book conservation.

The difference can sometimes mean thousands of dollars when

discussing high dollar key comic books. Do NOT press

a comic book with an iron.

HOW LONG DOES

IT TAKE TO LEARN?

Every person is different. Do you have the ability to troubleshoot?

Life experiences, patience thresholds, busy schedules, attention

to detail, and climate can depend on the speed of your learning

process. For the average person, it will take a minimum of

2 years to fully grasp all aspects of comic book cleaning

and pressing. There are varying degrees of learning the different

eras, thickness of books, spine bindings, and paper quality.

Experience, time, and patience all play an important factor

in this experience. As with anything else in life, it all

will depend on how much time you put into learning this procedure.

Over time, you will continue to learn new tricks, and develop

your own favorite methods and shortcuts as well.

SHOPPING CHECKLIST

For this guide, you will need basic comic book pressing

equipment that can be purchased online. Please

refer to our product links page for recommended products.

THE PRESS MACHINE

There are 3 main types of machines you’ll often hear

about:

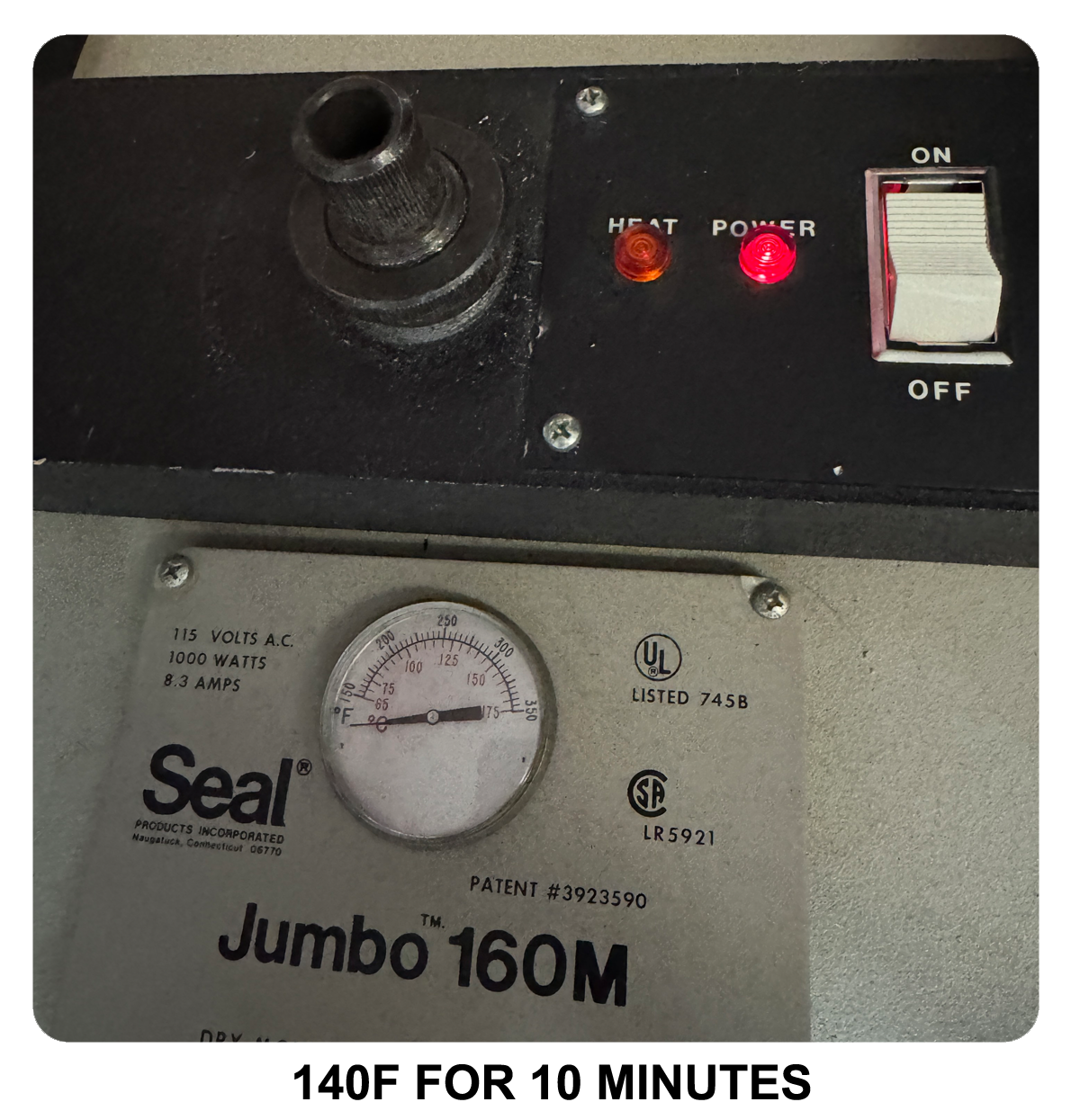

- Seal Dry Mount Press Machine, a flat-bed

style press adapted from the photography world.

- Clamshell Press Machine, which closes

like a clam to deliver simple, firm pressure. I prefer

to use the 15x15 Clamshell Press Machine, and the machine

of choice when writing my guides for comic book pressing.

- Swing Arm Press Machine, which uses

a pivoting heated plate for precise control and centralized

pressure. Swing arm machines are great for spine roll

repairs and squarebound comic books.

Each machine has its own strengths and learning

curve, and as you explore them you’ll get a sense of which

fits your setup best.

THE IMPORTANCE OF YOUR PRESSING

ROOM ENVIRONMENT

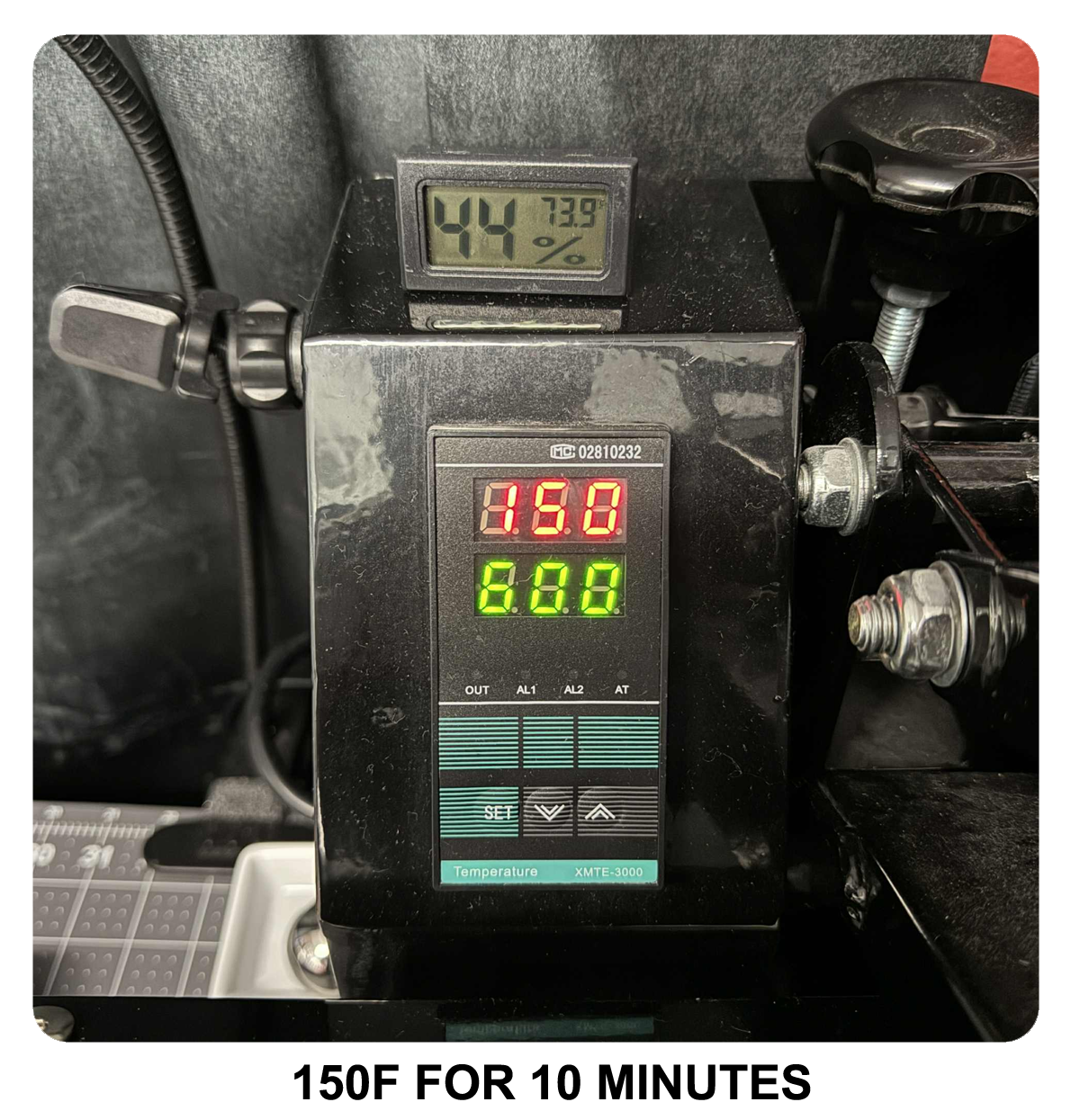

Pressing isn’t just about machines — it’s also about the space

you work in. Paper is highly sensitive to temperature and

humidity, which means the environment around your press can

directly affect your results. The ideal range for

pressing is 70–75°F (21–24°C) with a relative humidity of

40–50%. This range keeps the paper fibers flexible

enough to relax during pressing, but not so damp that they

swell or wrinkle. If your room is too humid, the paper can

absorb excess moisture, which often leads to problems like

spine waves, rippling, or even mold growth if books are left

unchecked. On the other hand, if your environment is too dry,

the paper becomes brittle and less responsive to pressing,

which increases the risk of tears, split spines, or color

rub.

MAINTAIN CONTROL OF YOUR ENVIRONMENT

To control your environment, many collectors use tools like

digital hygrometers (to measure temperature and humidity),

dehumidifiers or humidifiers (to stabilize the air), and even

air purifiers to keep dust away from books during cleaning

and pressing. By keeping your workspace stable, you’re not

only improving your pressing success rate but also protecting

your collection from long-term environmental damage.

Environment Must-Haves for Beginners

• Digital hygrometer/thermometer

– to monitor temperature and humidity.

• Dehumidifier or humidifier

– to keep relative humidity steady around 40–50%.

• Stable room temperature (70–75°F)

– avoid hot attics, garages, or damp basements.

• Air purifier – keeps dust

and particles away from books during cleaning and pressing.

• No direct sunlight – sunlight

can cause heat fluctuations and fade inks.

• Climate consistency –

don’t move books in and out of humid vs. dry spaces during

pressing.

• Avoid “problem rooms”

– open loft areas, high foot traffic zones, kitchens, bathrooms,

and laundry rooms all cause big swings in humidity and should

never be used for pressing or storing comics.

THE ORDER OF OPERATIONS

When performing comic book cleaning and pressing,

it’s critical to follow the Order of Operations so you don’t

waste time, cause damage, or miss important details. Following

the Order of Operations isn’t just about being organized

— it’s about protecting your comics and building good habits.

Pressing is a delicate process, and every step prepares

the book for the next one. If you skip inspection, you might

waste time on a comic that’s unpressable or even damage

it further. If you clean after pressing, you risk grinding

dirt into softened paper fibers. If you forget reversion

checks or proper storage, defects may come back before grading.

Each step is like a link in a chain — when followed in order,

the chain is strong; when skipped or scrambled, the chain

breaks.

The Order of Operations

for Cleaning & Pressing Comic Books:

1. Inspection for Rejects –

Identify books that are too fragile or have too many unpressable

defects. PRO TIP! Color-breaking creases,

ink loss, or brittle paper can’t be fixed by pressing.

2. Photography (Before)

– Document the book’s condition to track progress. PRO

TIP! Take clear shots under good light; clients

appreciate strong before/after records.

3. Dry Cleaning / Stain Removal

– Remove surface dirt or light soiling before adding heat

or moisture. Follow basic free dry cleaning tips at this

guide. Warning: Never

dry clean after pressing — it may be more difficult to lift

light soiling or dirt once it’s been flattened into the

paper.

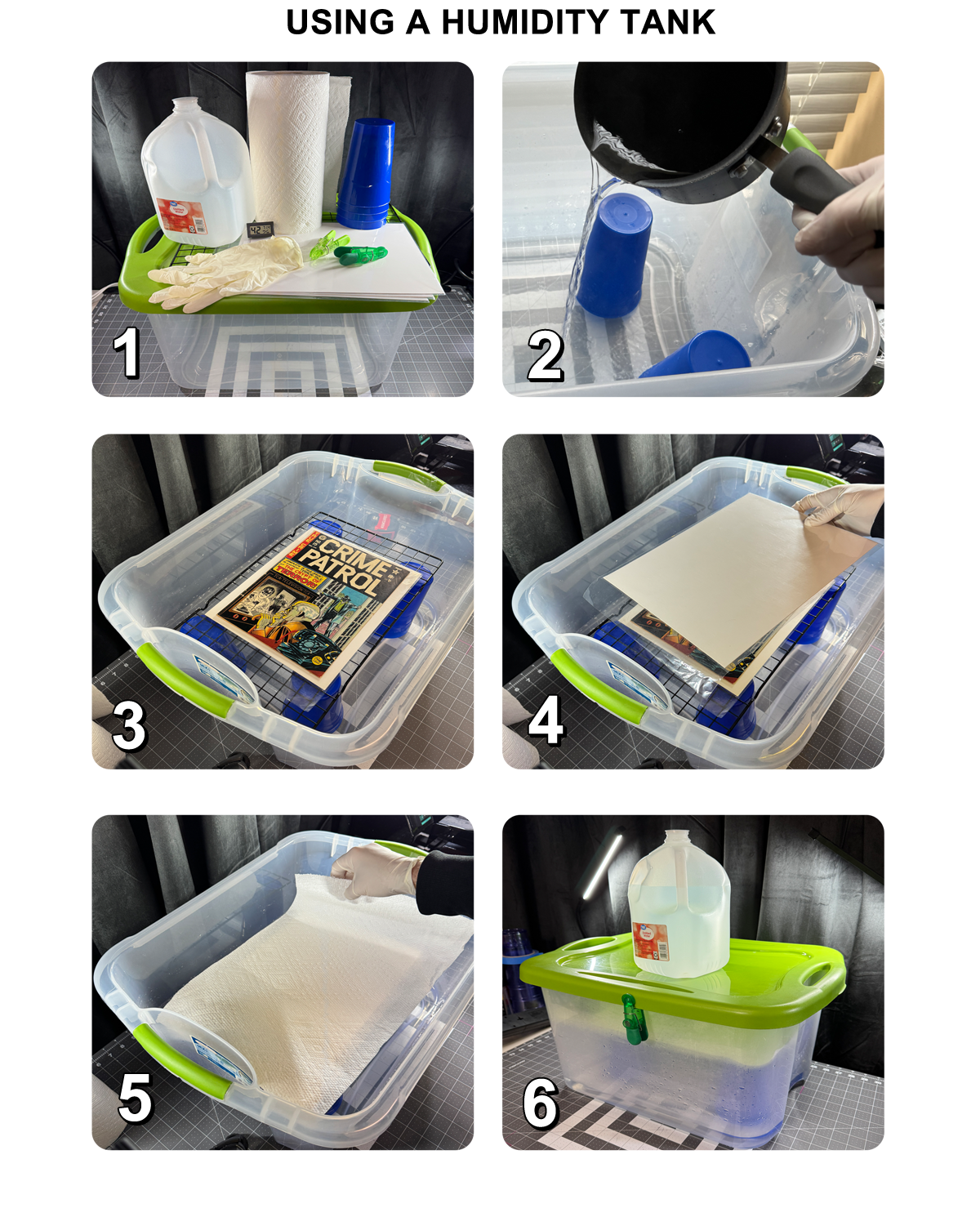

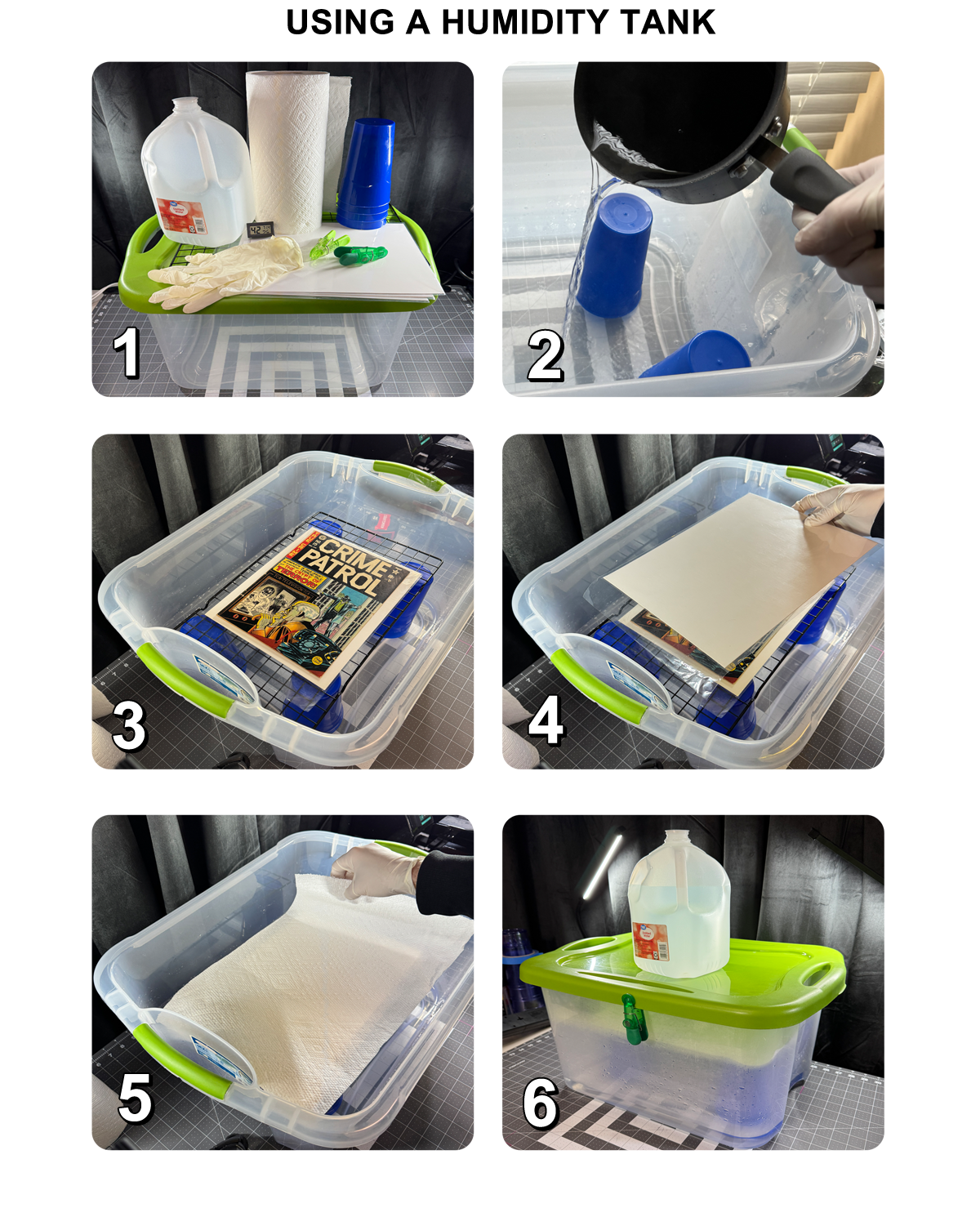

4. Humidity Tank – Relax

the paper fibers to prepare for reshaping. PRO TIP!

Keep humidity controlled (40–50%) in the press room — too

much causes waves or oversaturation.

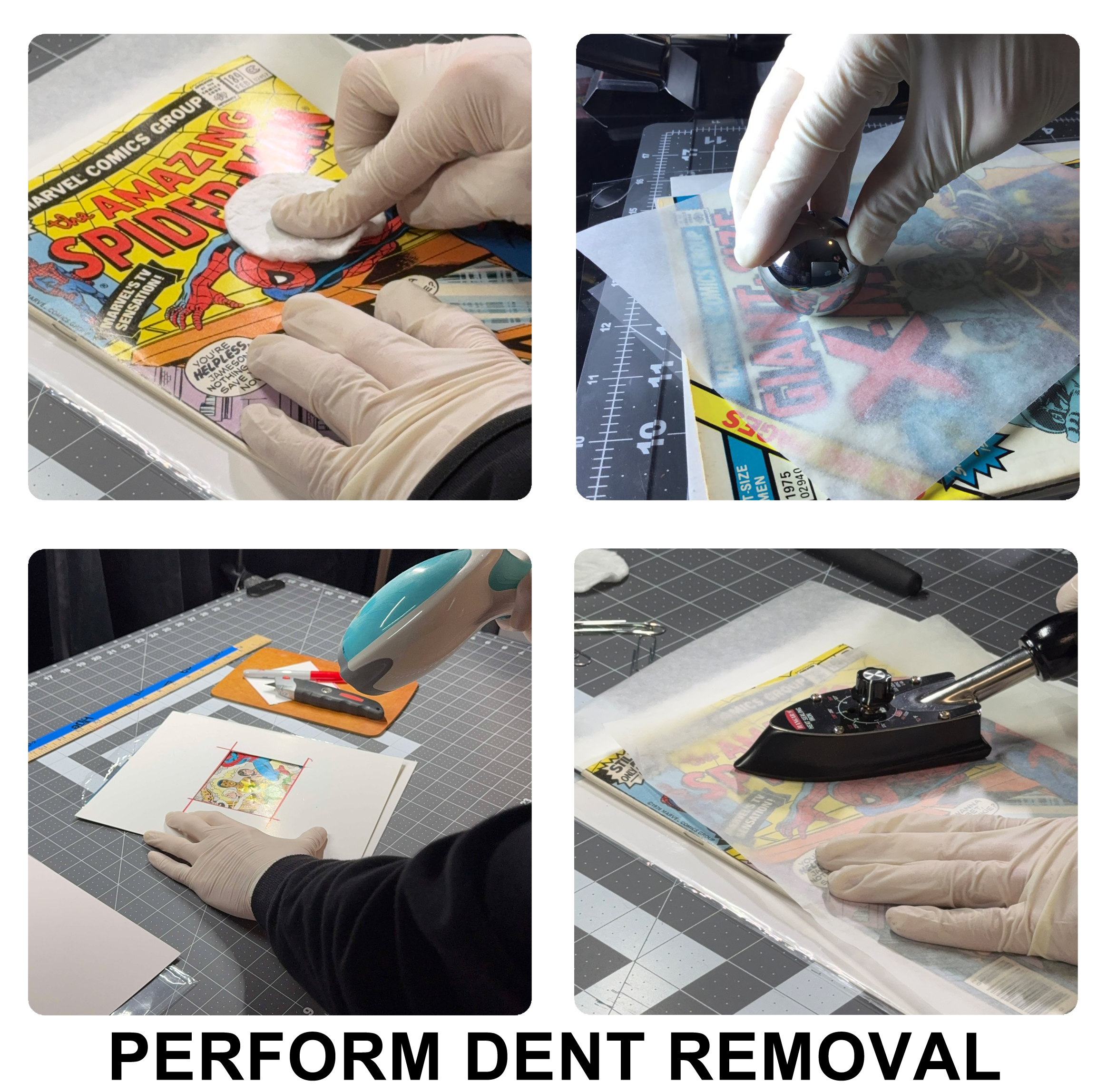

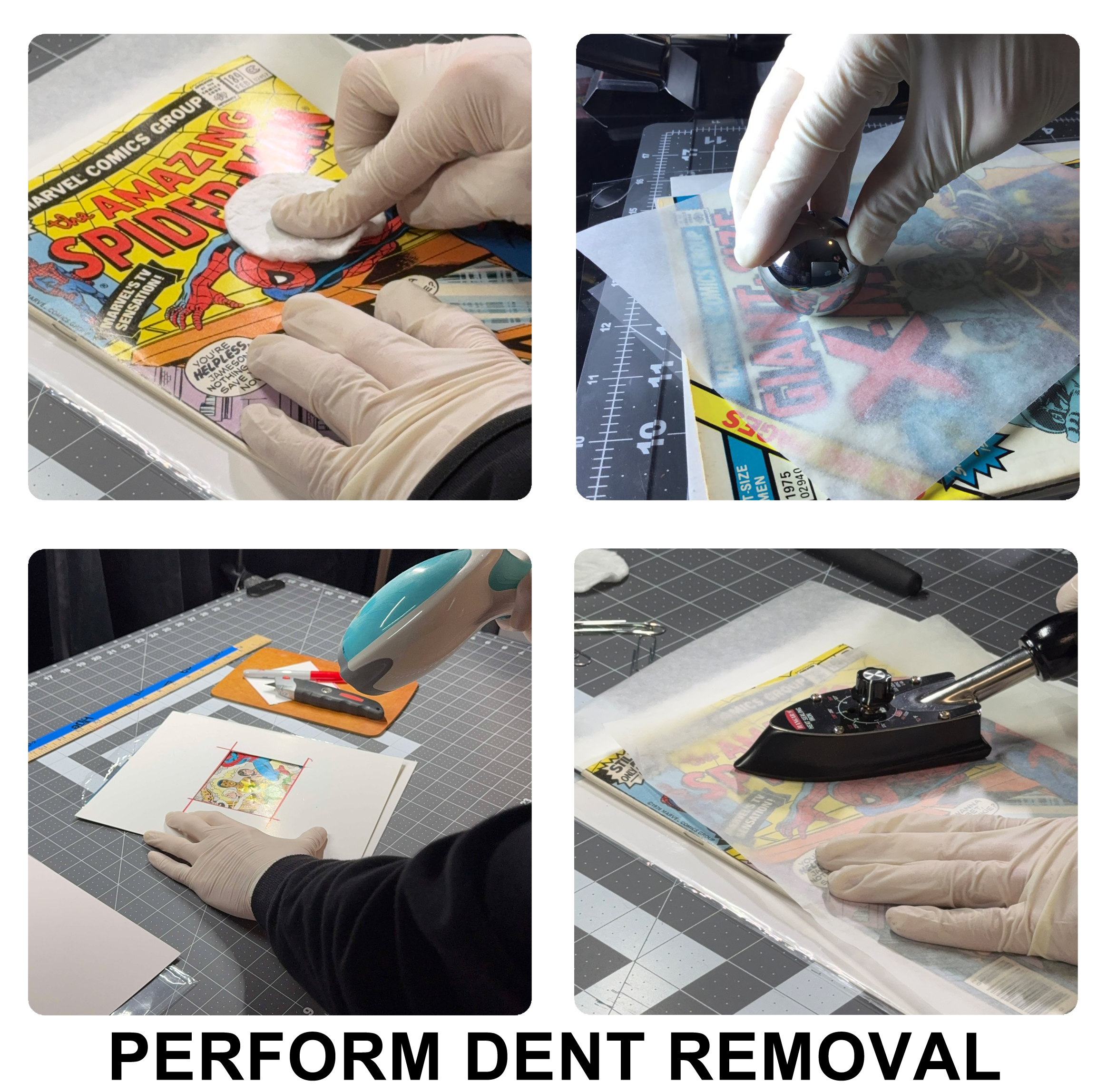

5. Dent Removal – Address

stubborn divots, impressions, or spine dents while the paper

is malleable from the humidification step. PRO TIP!

Use tools like a steam gun, steel ball bearing, and a tack

iron for targeted dent removal.

6. Pressing – Apply controlled

heat and pressure to flatten defects. Warning:

Press at safe temperatures (around 130–160°F)

— overheating risks gloss bubbling, flaring, warping, fusion.

Always allow a suitable wait time of 12-24 hrs. before removing

from press machine.

7. Reversion Check – Let

the book rest for several days and monitor for defects returning.

PRO TIP! Store in bag/board flat for 2–5

days; unstable climates cause reversion.

8. Photography (After)

– Record the results for comparison and grading prep. PRO

TIP! Side-by-side before/after photos prove your

work and protect against disputes.

9. Proper Storage – Bag,

board, and keep the book in a stable environment.

Warning: Avoid basements, attics,

or kitchens — heat and humidity swings cause reversion.

10. Shipping / Grading

– Send the book safely once fully settled. PRO TIP!

Use sturdy Gemini mailers or CGC-approved boxes

to prevent shipping dents.

PRACTICE ON

PRESSING 7 TYPES OF BOOKS

You will need to practice first on 7 basic types of comic

books to learn the process slowly. Practice on your own books

first. Practice treating each book as if it were priceless.

- Golden Age Books are brittle, require

steam or humidity, and require extra care when handling.

- Silver Age Books can also be quite

brittle, and have edgewear like crazy. Watch for rusty

staples.

- Bronze Age Books have a different

type of paper, semigloss and with inserts.

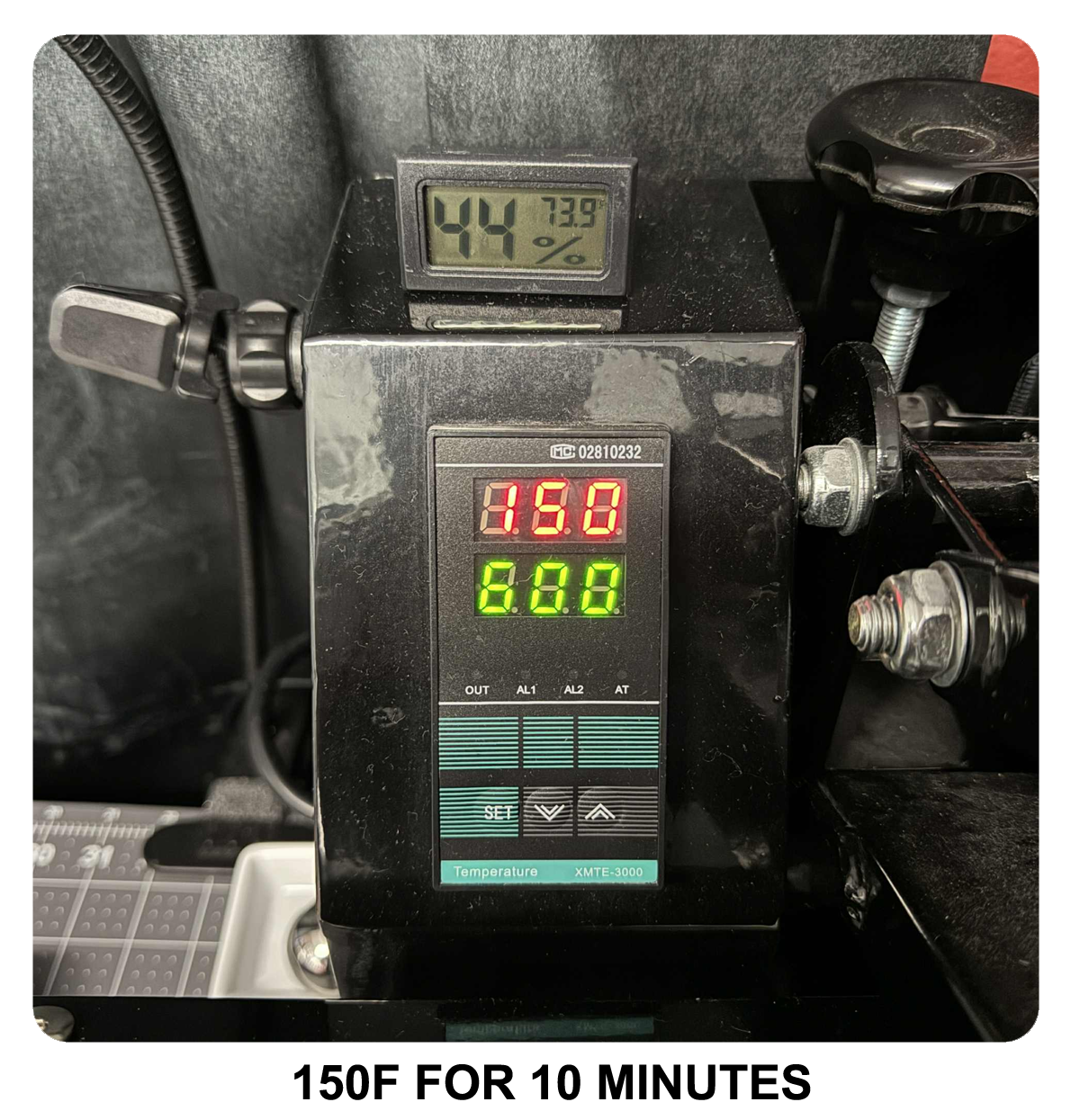

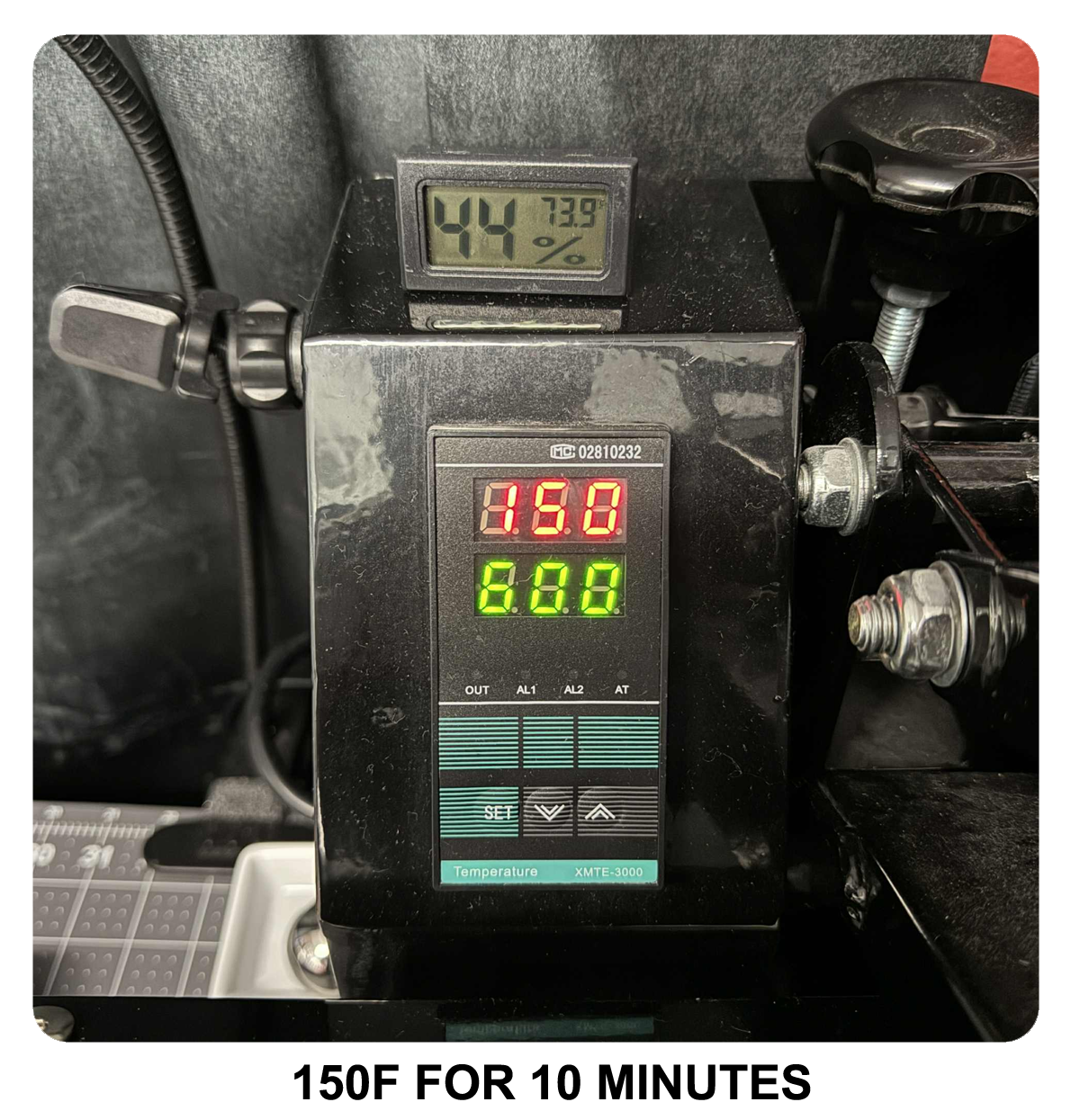

- Modern Age Books with Glossy Magazine

Paper books can have pages stick together if too hot!

Under 150F and under 10 minutes at a time. The pages will

stick together otherwise and you will create a razor blade

comic book.

- Foil books (Convention exclusives)

are more intimidating if anything. Watch your fingerprints!

Always wear gloves. Same rules apply as if it were a glossy

modern with glossy pages. Too hot and too long will ruin

the book!

- Digital Code Inserts Marvel and DC

both now have online digital code inserts found at the

last 4-6 pages. You will need to use cardstock paper to

prevent the 1″ or 2" square digital code from imprinting

on last 4-5 pages and back cover.

- Gimmick Books are books that have die

cut, embossed, glow-in-the-dark, hologram, or lenticular

covers. Embossed covers will need to be cushioned with

cardstock paper. Gimmick books can be safely pressed using

less pressure under low heat (150-155 degrees) for 5-7

minutes and left overnight in a cold press machine. Heating

up glow-in-the-dark comic book covers actually re-activate

the glow powder crystals in the paint, which effectively

make the glow effect appear brighter with bolder colors.

All of these books were pressed using methods outlined

in this guide and on my youtube channel. You too, can achieve

similar results.

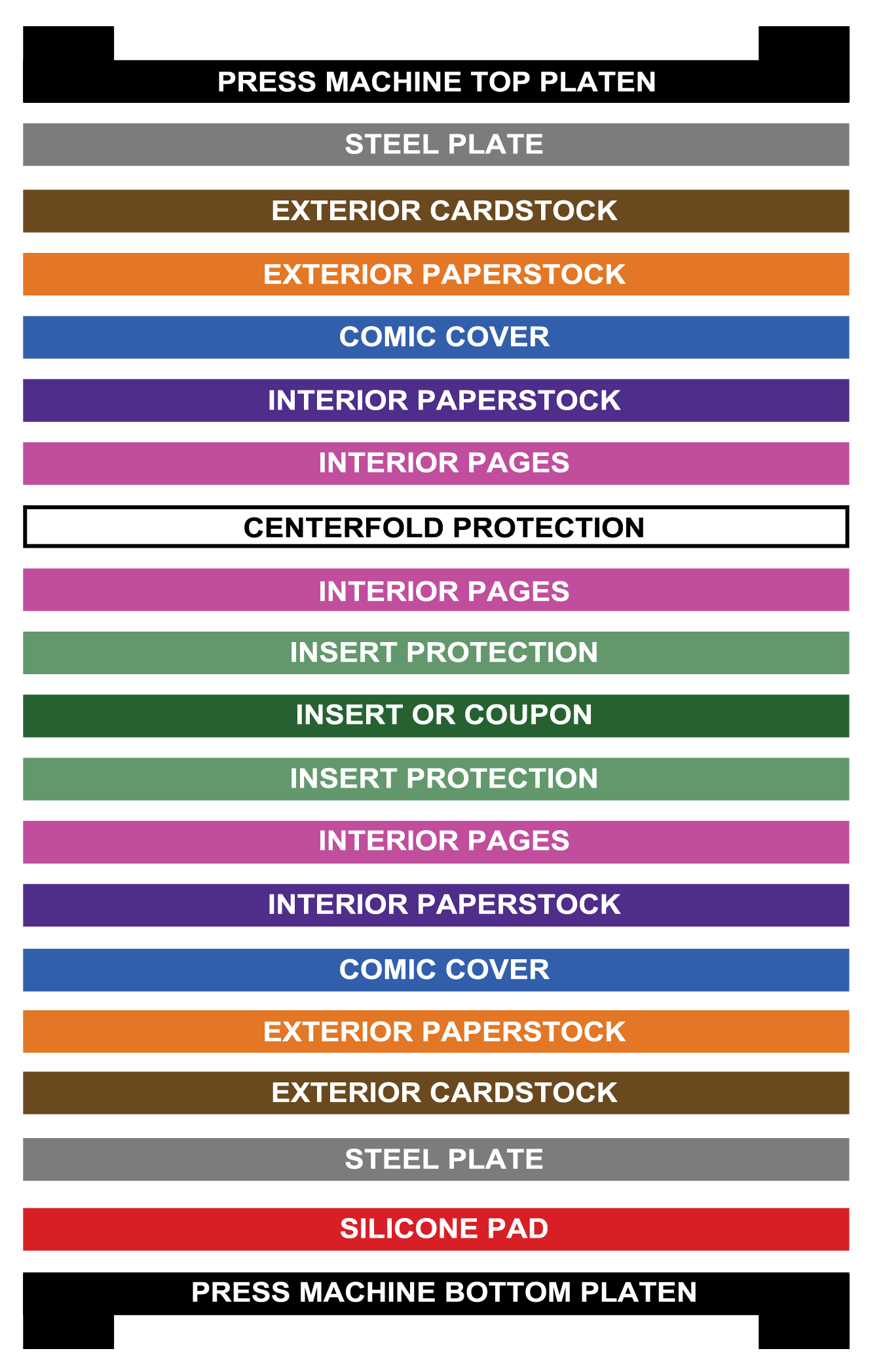

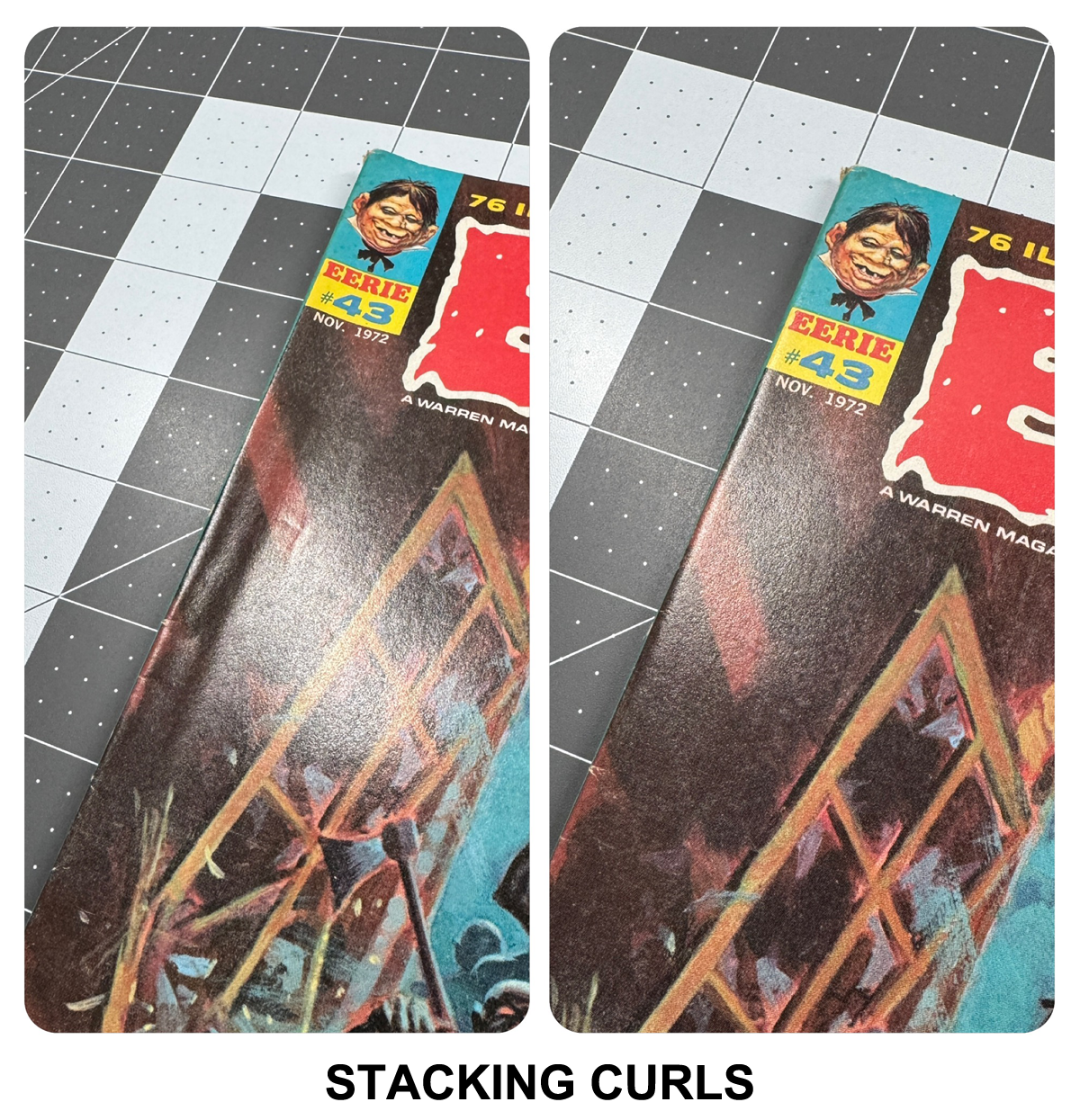

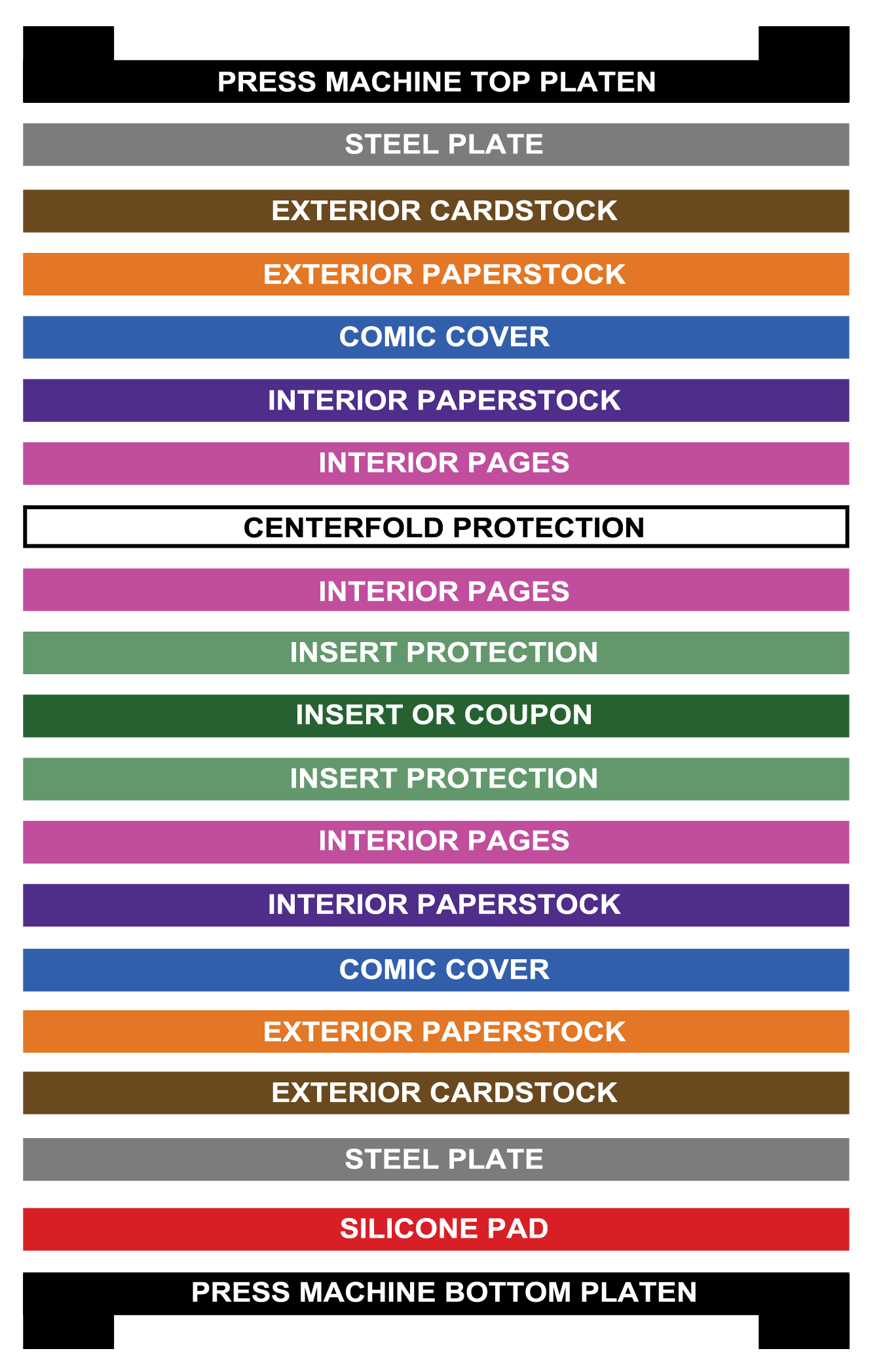

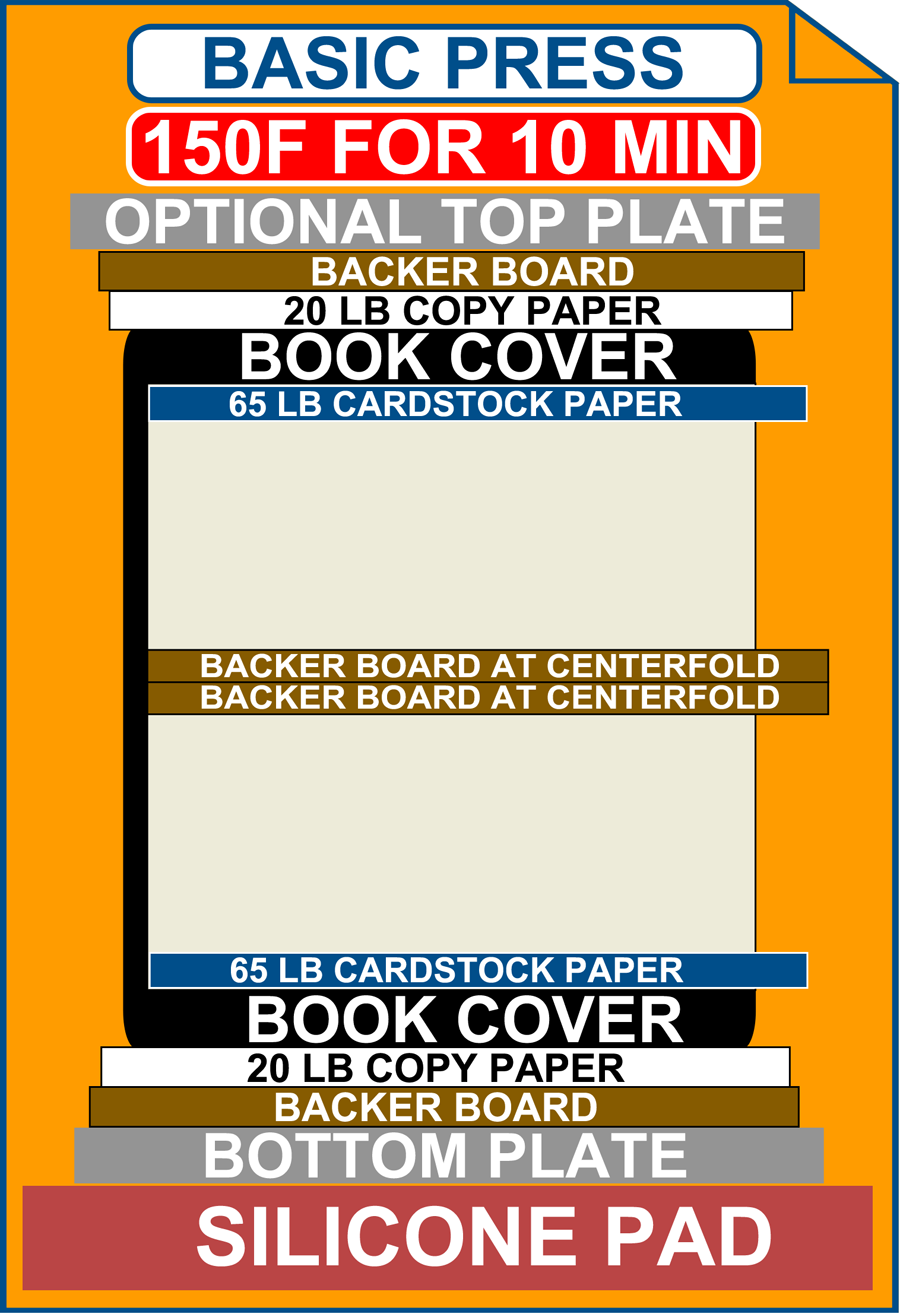

STACKING LAYER RECOMMENDATIONS

Before beginning any procedures outlined on this page, make

sure that all comics have been thoroughly dry cleaned and

wiped of any fingerprints or light scratches. To learn more

about pressing and using all the stacking layers correctly,

please follow the diagram found below. You will insert paper

or cardstock layers inside the interior pages of a book

in order to push out the dents and defects during the actual

pressing procedure. The Basic Press is the core method for

all satellite formulas. Formula recommendations are altered

depending on the age of the book, type of cover, and the

type of interior paper stock. The Basic Press Formula work

well for most comics and magazines but is largely dependent

on the fragility of the cover and the spine.

PRESSING OPTIONS

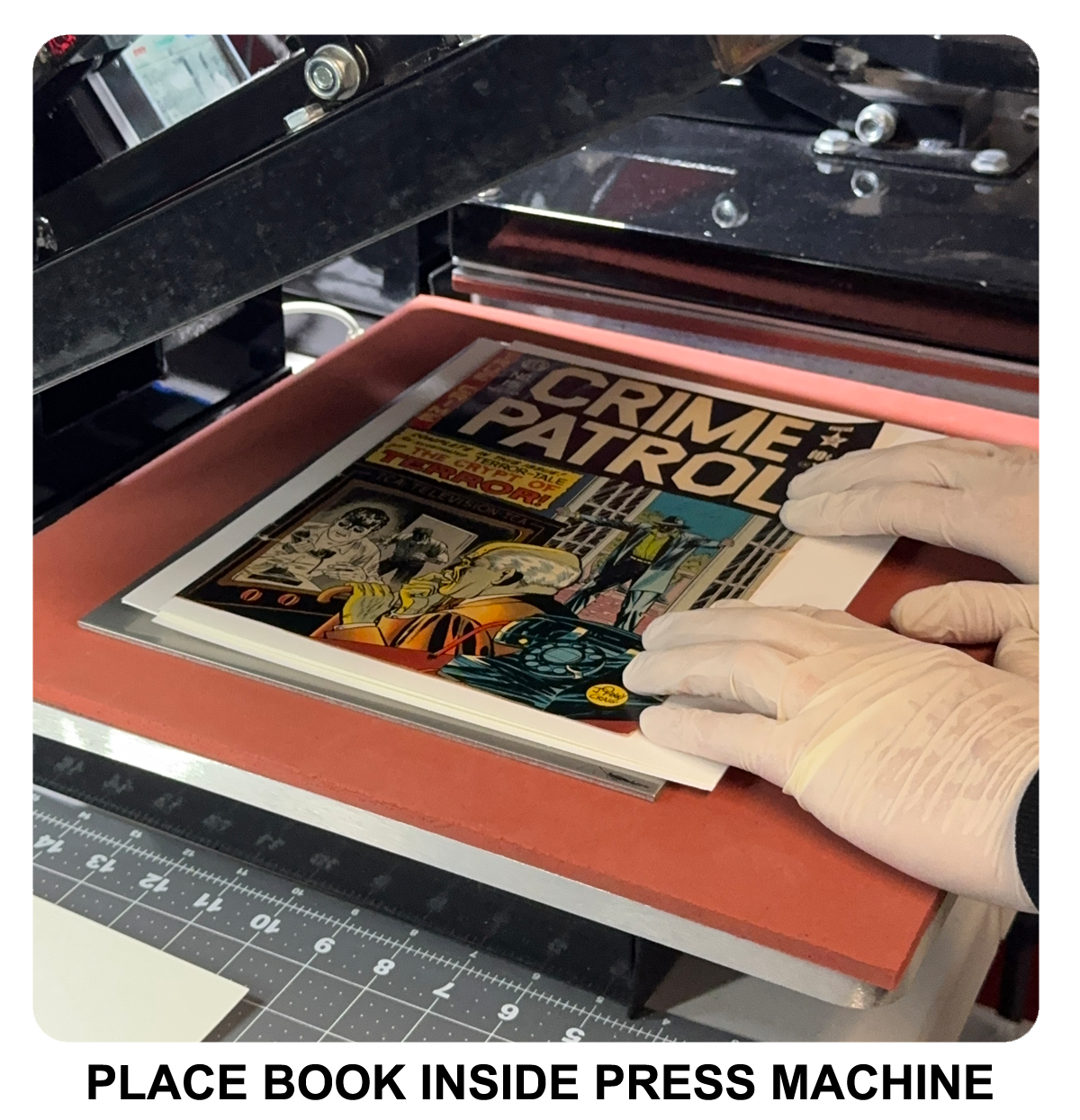

Books are typically placed in the press machine with the

most defects facing up towards the heated platen. You have

a few options for the stacking layer materials (choose one

option for each layer):

INTERIOR PAPERSTOCK (INTERIOR PAGES

OF BOOK)

• 65 LB CARDSTOCK PAPER (Primary stacking layer, underneath

covers or after pages 1 or 2)

• 110 LB CARDSTOCK PAPER (Staple protection, insert protection)

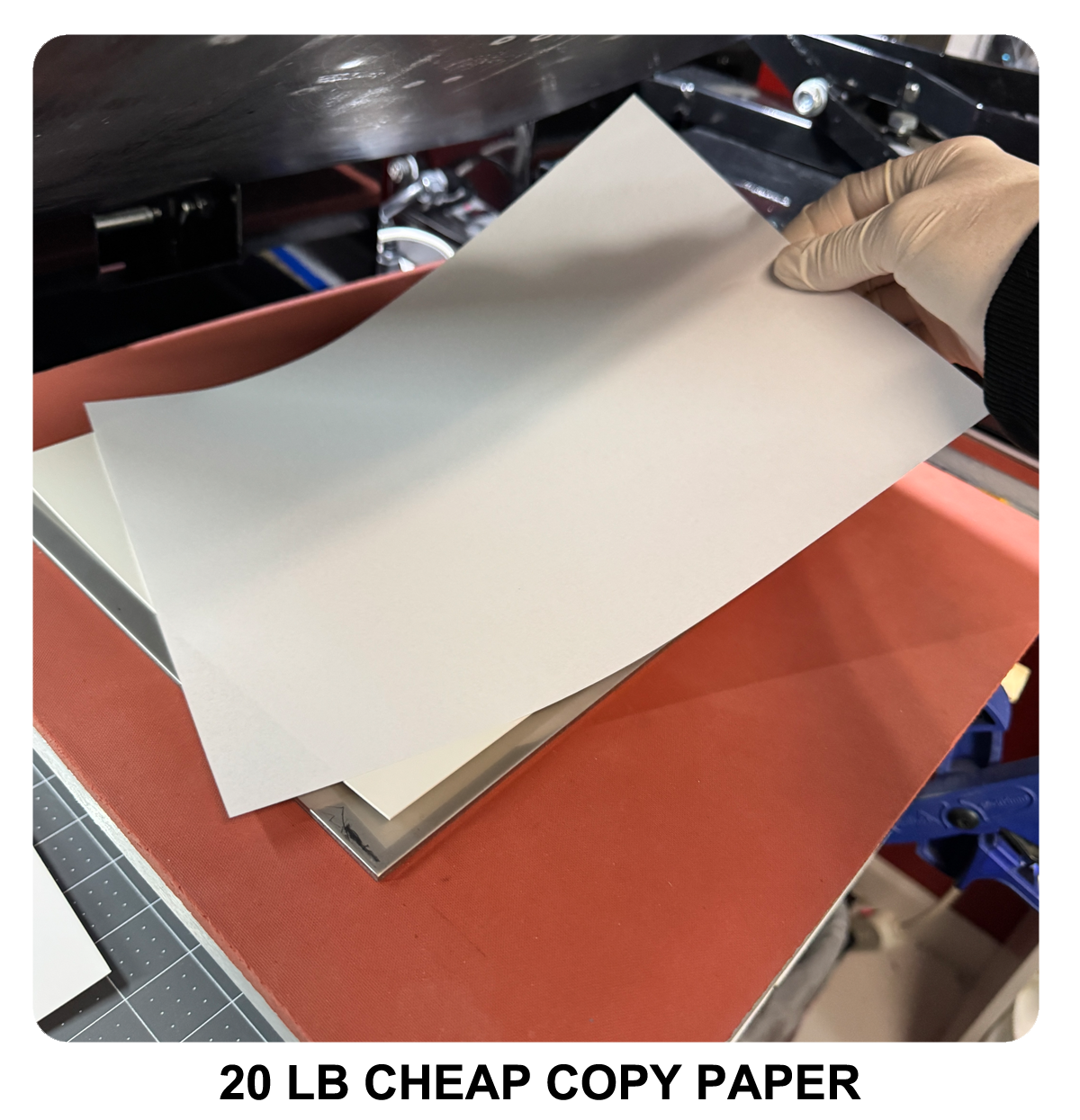

• 20 LB INKJET COPY PAPER (Secondary stacking layer, underneath

covers or after pages 1 or 2)

• SILICONE RELEASE PAPER (Dent removal, before any insert

envelope adhesive backing strip)

• NONE (Reset underhanging covers)

INSERT PROTECTION (BEFORE AND AFTER

EACH INSERT PAGE)

• 65 LB CARDSTOCK PAPER (Recommended for most inserts)

• 110 LB CARDSTOCK PAPER (Recommended for DC Comics digital

code squares)

• 20 LB INKJET COPY PAPER (5 sheets, if you do not have

65 lb cardstock paper)

CENTERFOLD PROTECTION (CENTER OF BOOK)

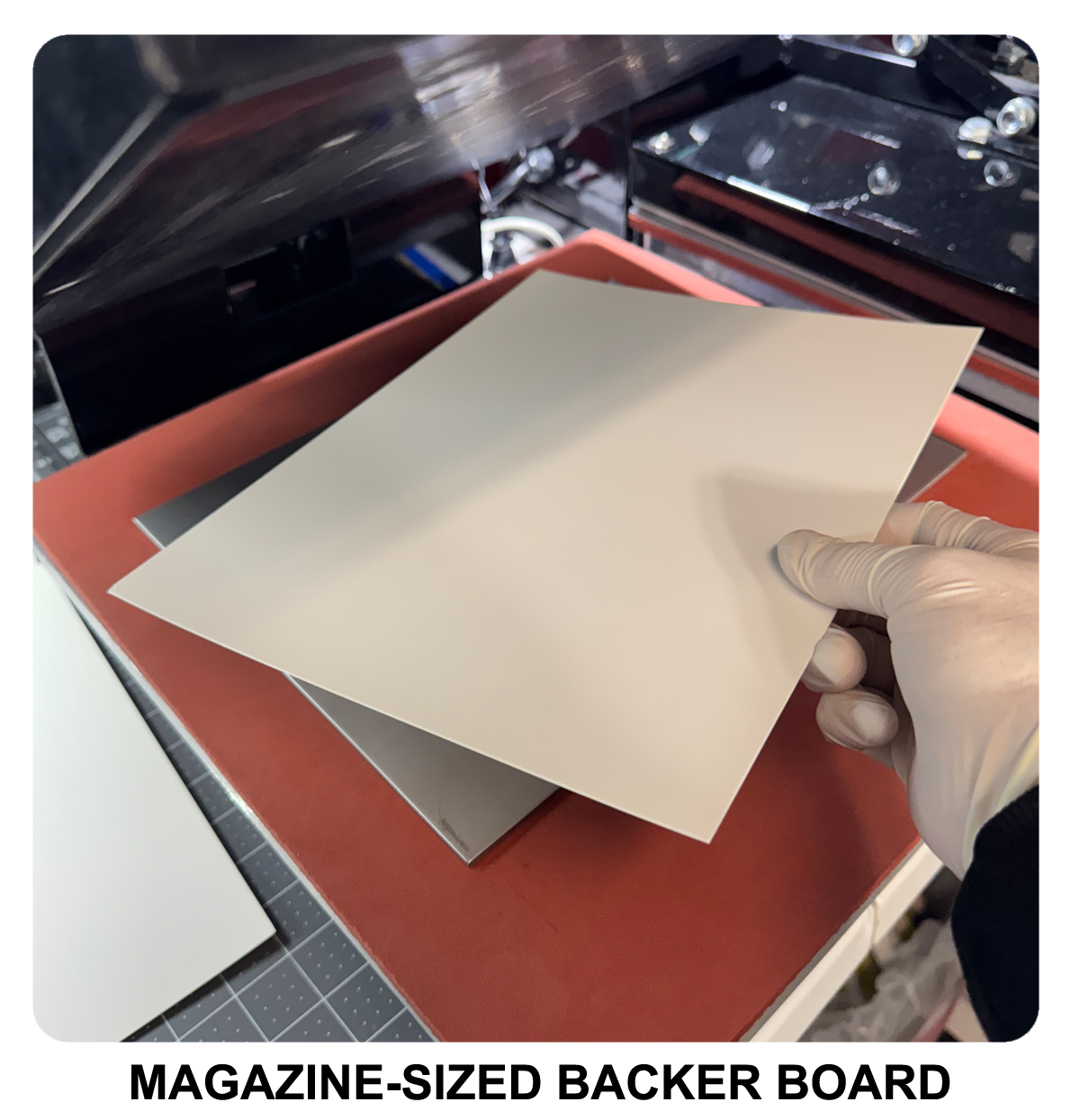

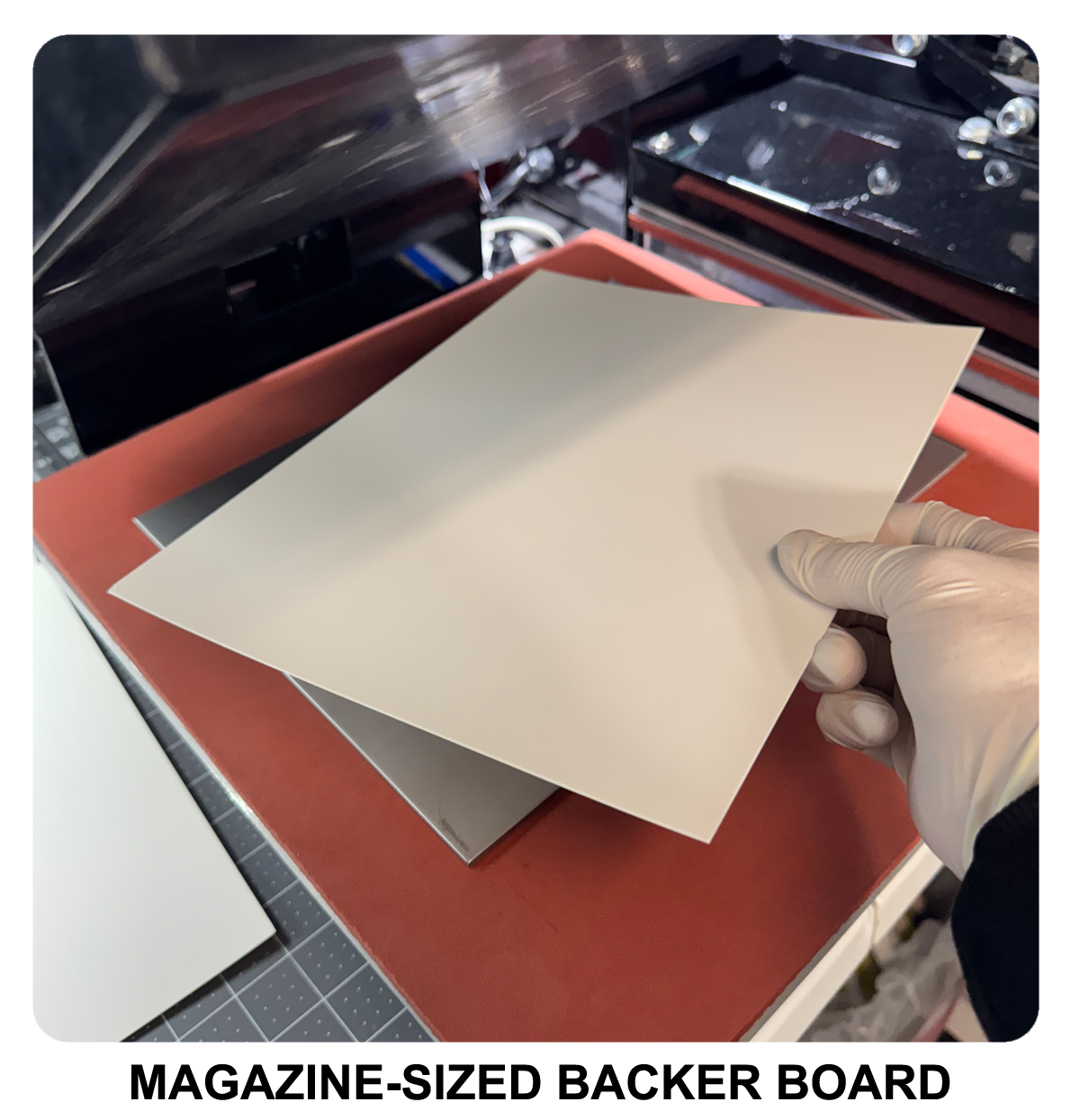

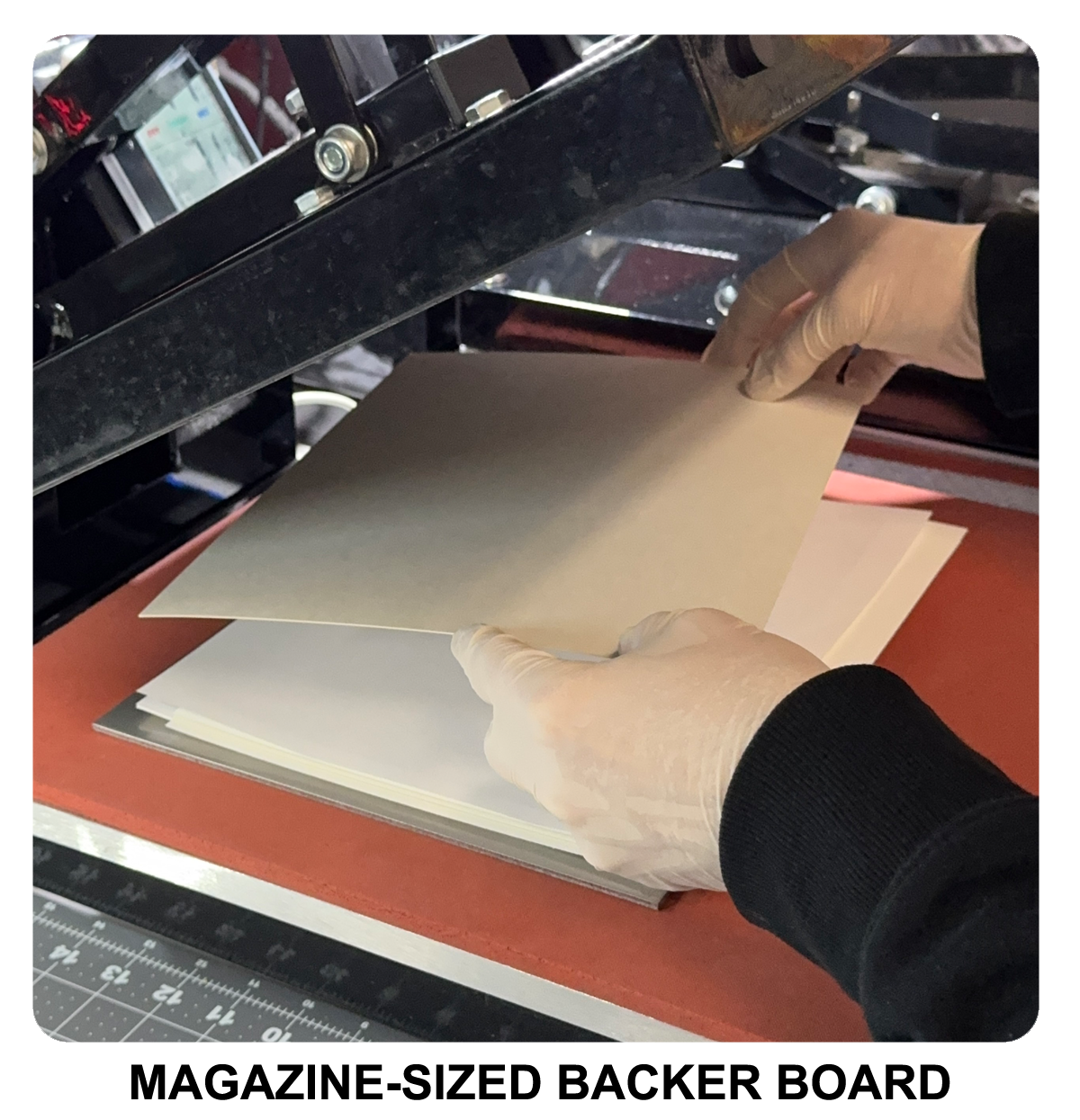

• MAGAZINE-SIZE BACKER BOARD (Single)

• TWO MAGAZINE-SIZED BACKER BOARDS (Double)

• FULL-BACK (Substitute for using two magazine-sized backer

boards)

• 65 LB CARDSTOCK PAPER (Prestige Format, Squarebounds,

Giant Sized glued spines)

EXTERIOR PAPER STOCK (OUTSIDE BOOK

COVERS)

• 20 LB INKJET COPY PAPER (All press stages on all comic

books and magazines)

• SILICONE RELEASE PAPER (Dent removal)

• 110 LB CARDSTOCK PAPER (Die cut covers, gimmick covers,

embossed covers)

EXTERIOR CARD STOCK (OUTSIDE BOOK COVERS)

• MAGAZINE-SIZE BACKER BOARD (Top and bottom outermost stacking

layers)

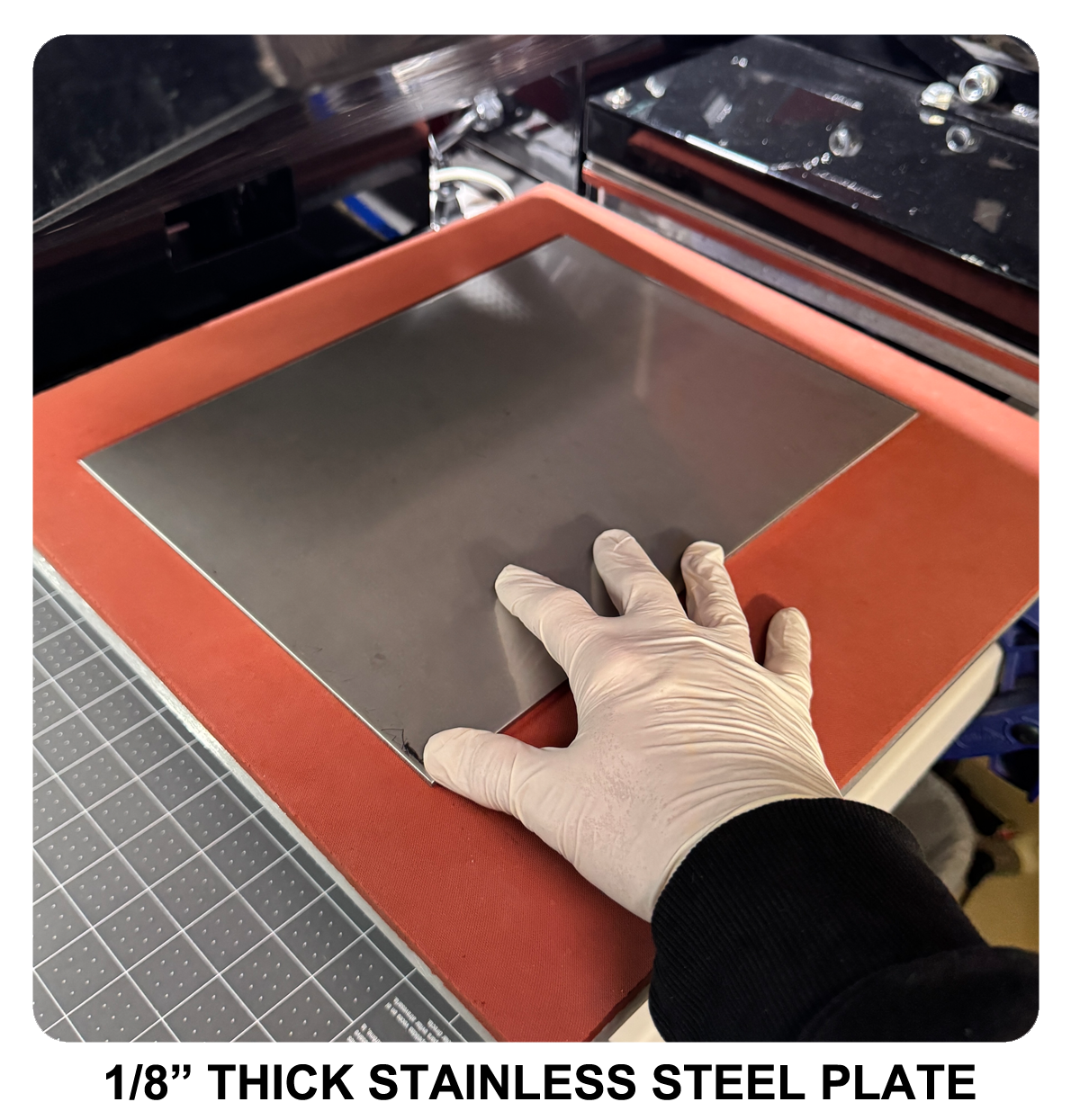

EXTERIOR RIGIDITY (OUTSIDE THE EXTERIOR

CARD STOCK LAYERS)

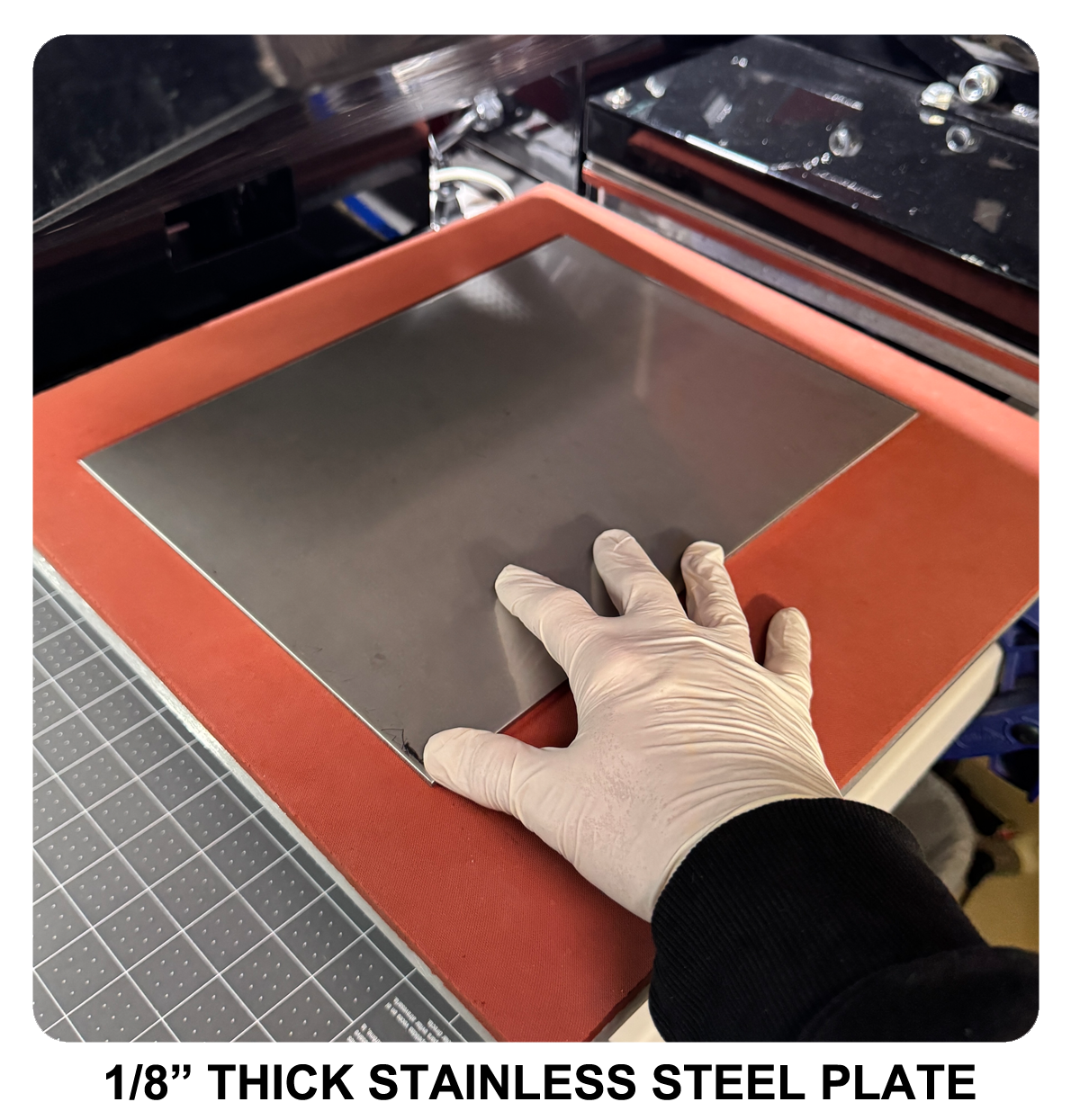

• STAINLESS STEEL PLATES (x2) (All press stages on all comic

books and magazines)

• ALUMINUM PLATES (x2) (All press stages on all comic books

and magazines)

• ½” or ¼” THICK FOAM BOARD (Flattening spines – cover side

down, staples up)

• THREE MAGAZINE BACKER BOARDS (x2) (Recommended if you

don’t have plates)

THE BASIC PRESS METHOD

Make sure all dry cleaning is done first.

The Basic Press Method is the basis for all satellite methods

outlined on this page. This is the full summary while performing

the Basic Press Method:

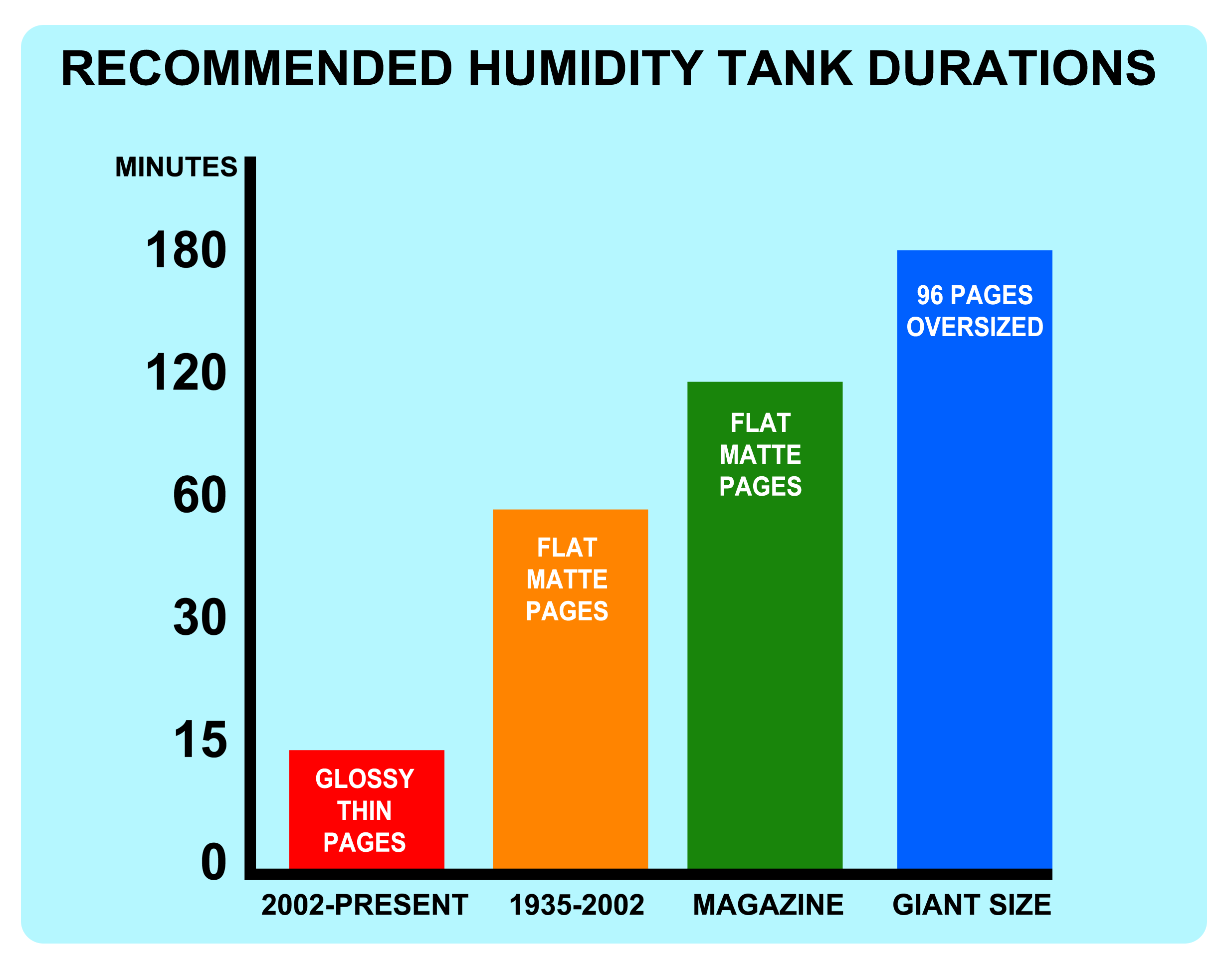

1. Place comic book on an elevated platform

in a humidity tank with a fresh gallon of

boiling water. The water line should be 1" to 2"

from the bottom of tank. Vintage comic books with flat matte

interior pages should be placed inside the humidity tank for

1 hour. Brand-new comic books with glossy thin interior pages

should be placed in the humidity tank for no longer than 10

to 15 minutes.

2. Perform dent removal procedures if required.

For vintage books with flat matte interior pages, apply a

damp cotton round to defect area and roll a steel ball bearing

around gently over the defect. Any book with glossy thin magazine

style interior pages should have light steam applied to the

defect area using a cut out backer board. Alternate methods

with a tack iron to apply localized heat to defect area. Proceed

to Step #3 while you are still finishing up dent removal.

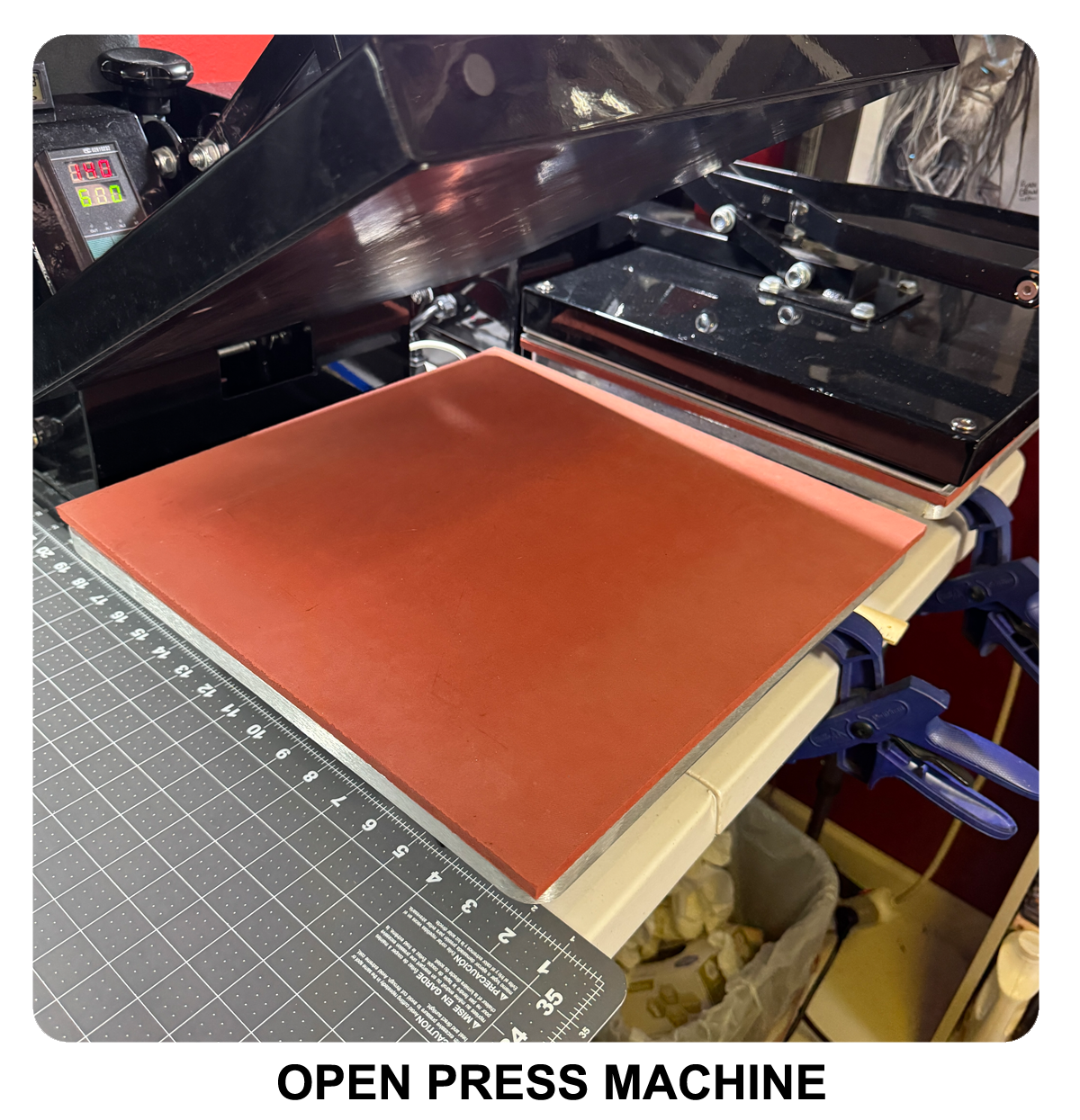

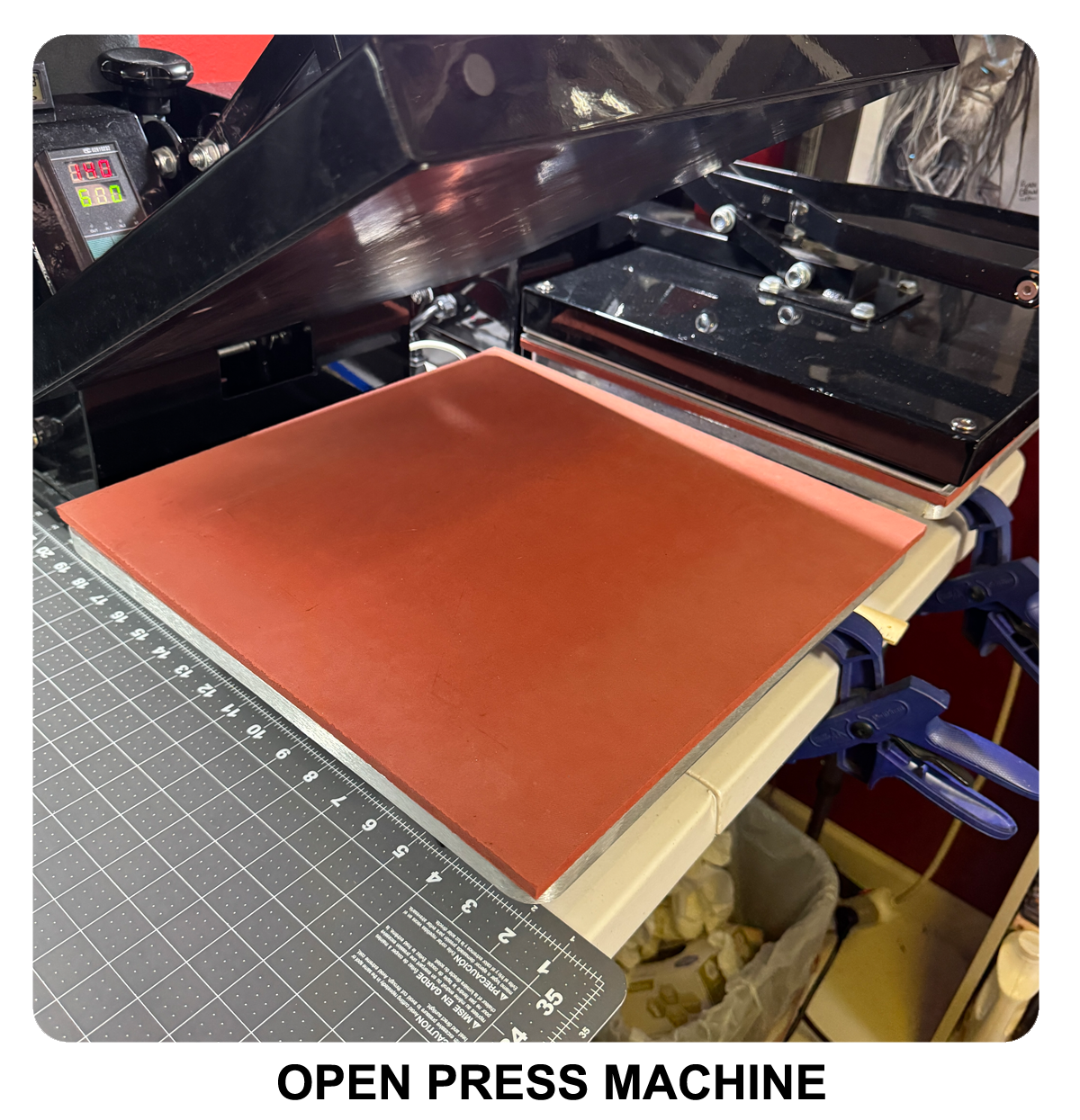

3. Open press machine. Find the power switch on your press

machine. Turn ON the

press machine.

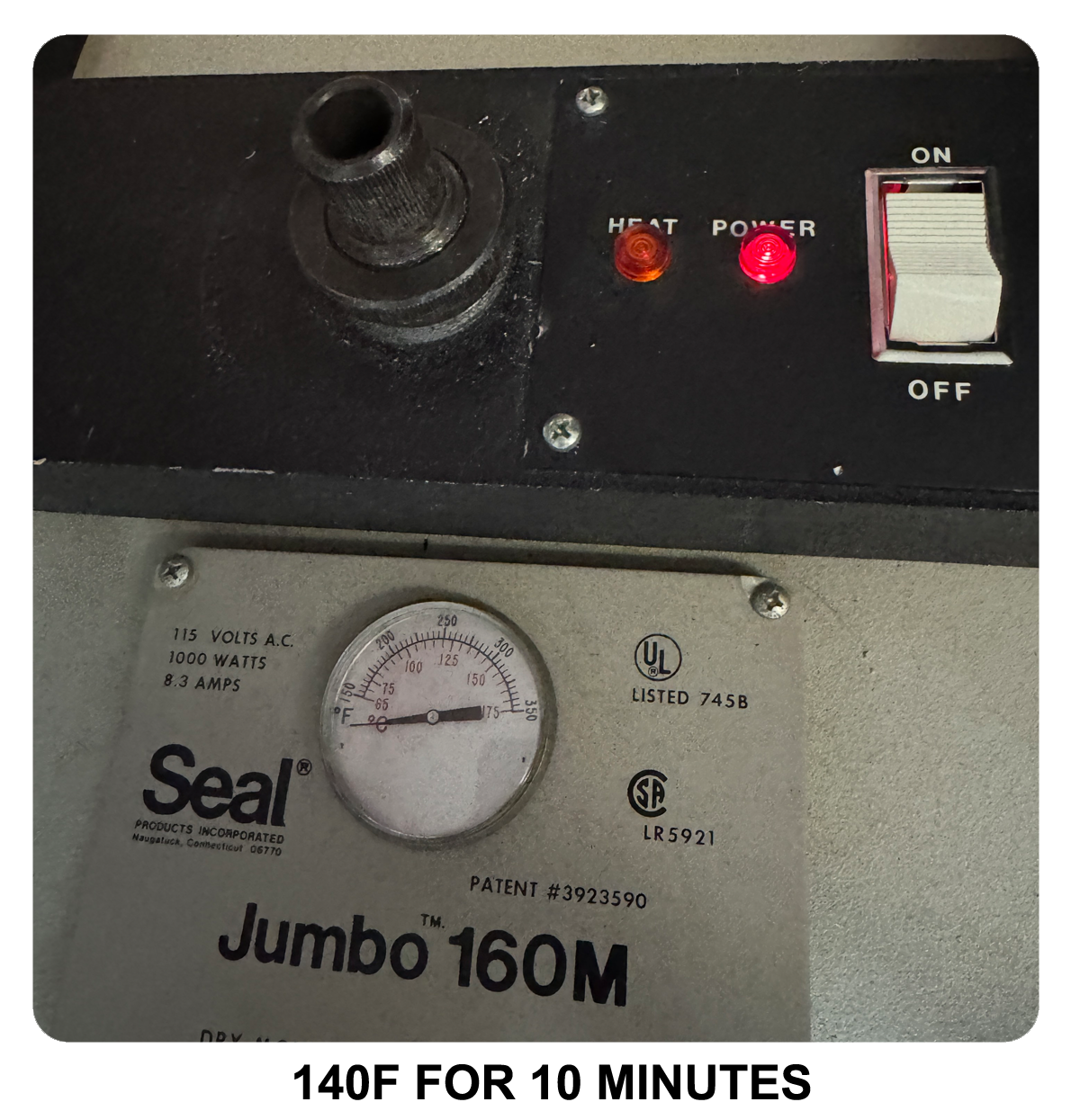

4. Preheat machine to the recommended temperature

and time duration as outlined in the Basic Press Method stacking

formula. 150F for 10 minutes.

5. Dry mount laminating press machines should set the temperature

to 10 degrees cooler than recommended due

to slower warmup and cooldown times, which equals longer heat.

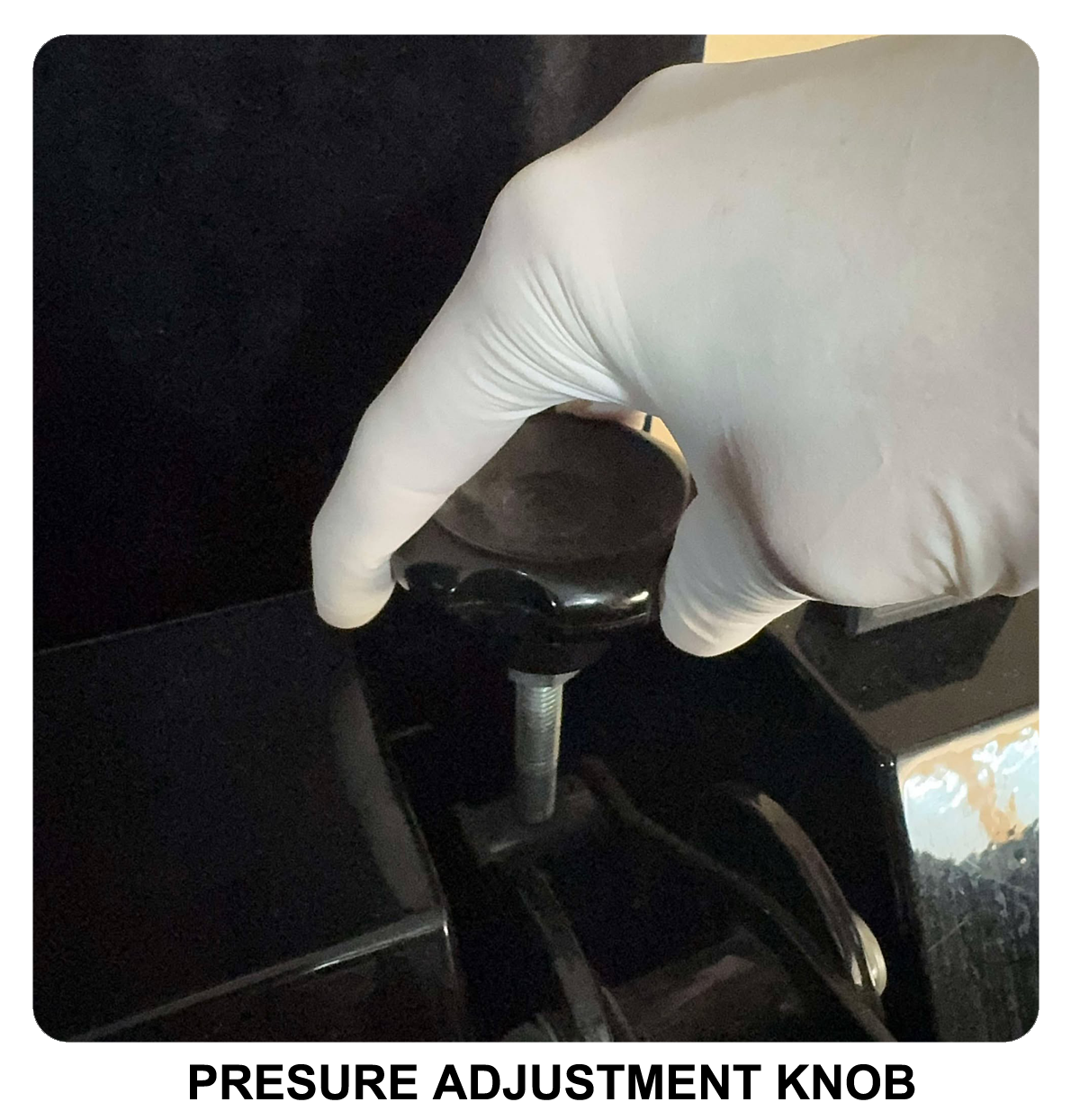

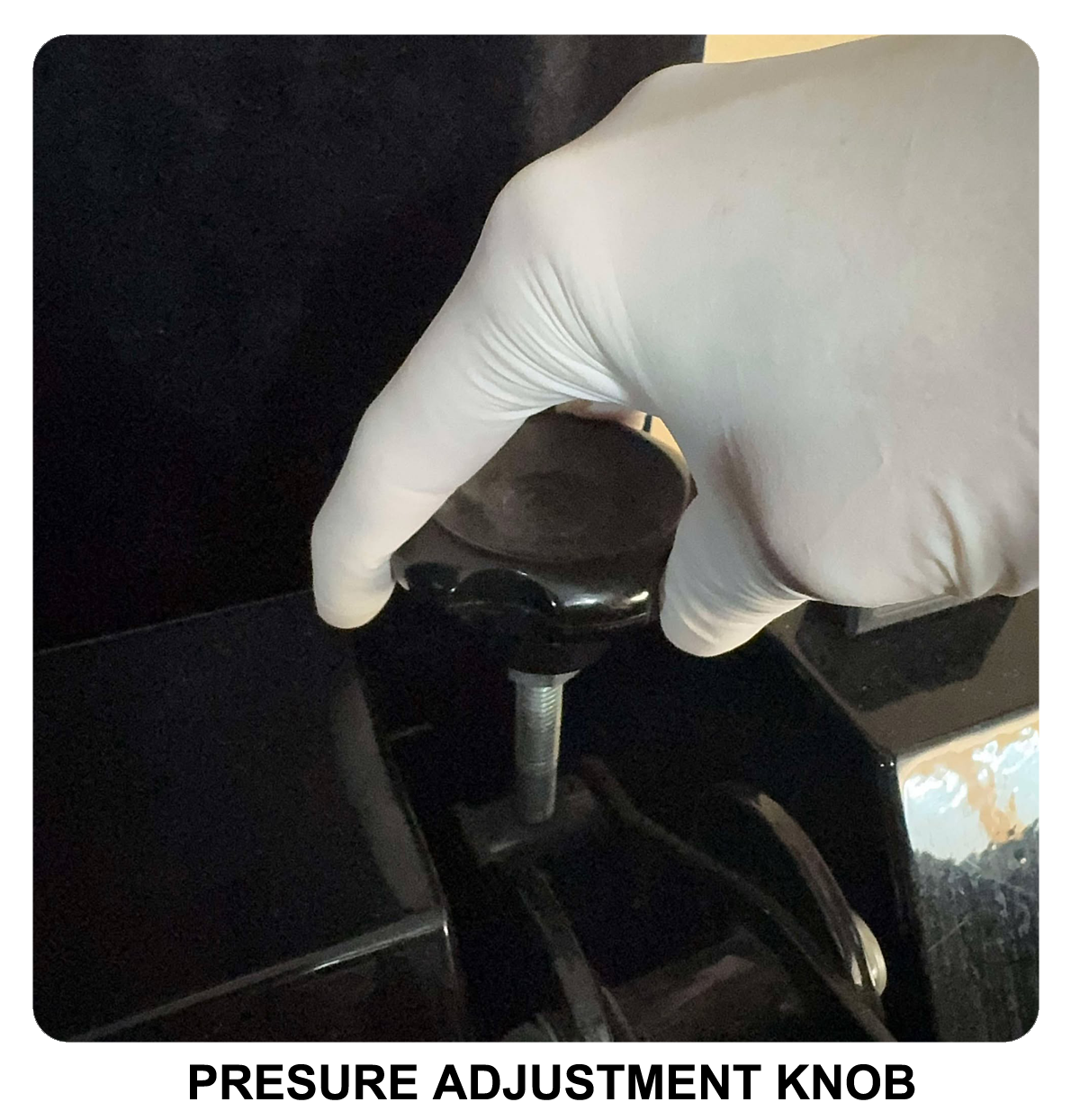

6. Turn pressure adjustment knob and measure

gap thickness for spine of book. The pressure adjustment knob

for swing arm machine is located at the top center of unit.

For clamshell and swing arm machines, turning the knob clockwise

increases pressure. For dry mount laminating press machines,

there will be two knobs. The larger knob must be loosened

first before adjusting pressure with smaller knob. The smaller

knob must be turned counter-clockwise to increase pressure,

which is the opposite of the two other machines.

7. Place bottom steel plate on silicone mat

of press machine. Plates should always be galvanized, stainless-steel,

or aluminum to prevent rust. Sizes can be 15x15, 12x10, 9x12

or 8x11.

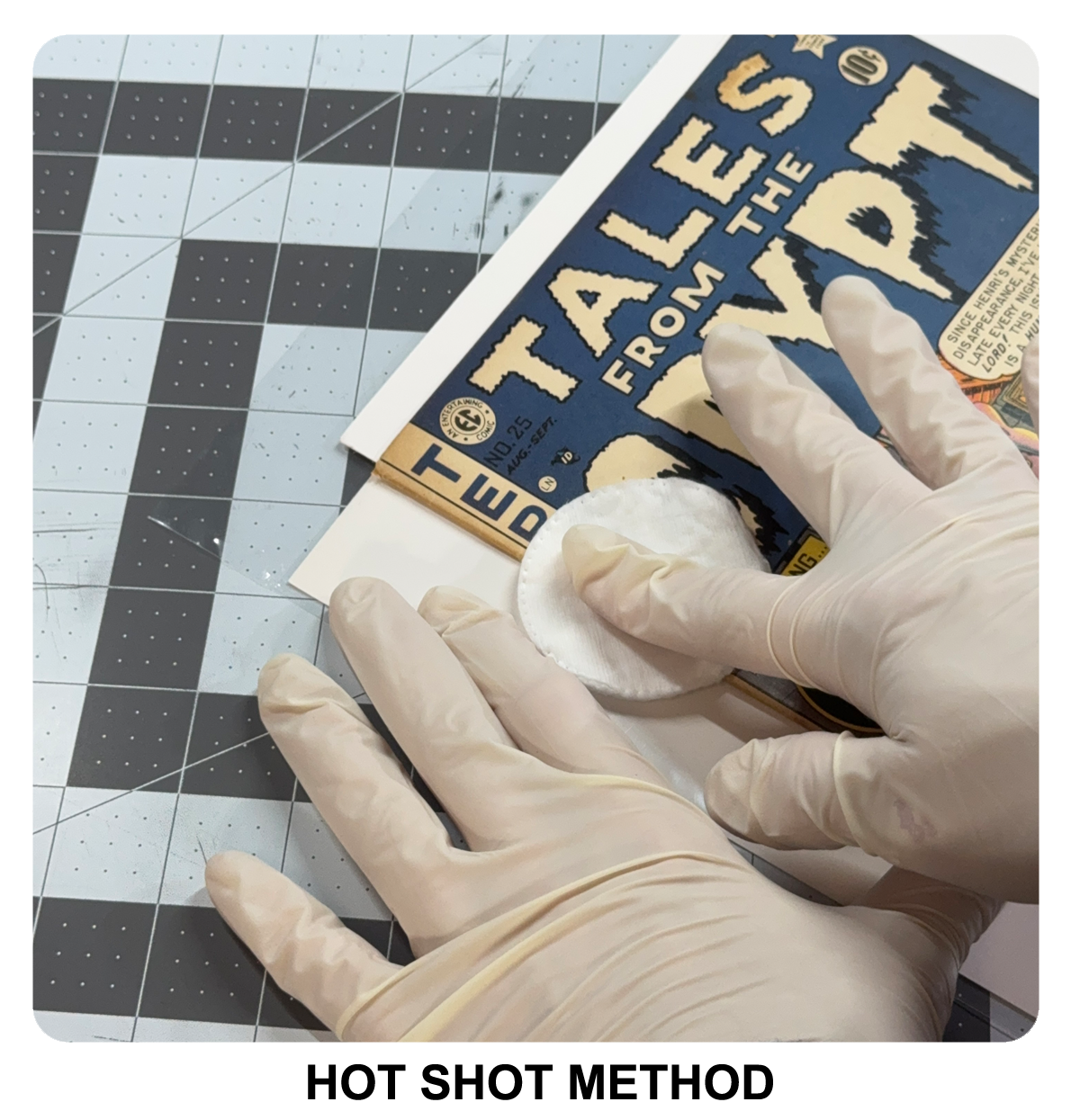

8. For books printed from 1940-2001 with flat matte interior

pages that feature heavy deep denting or deep indentations

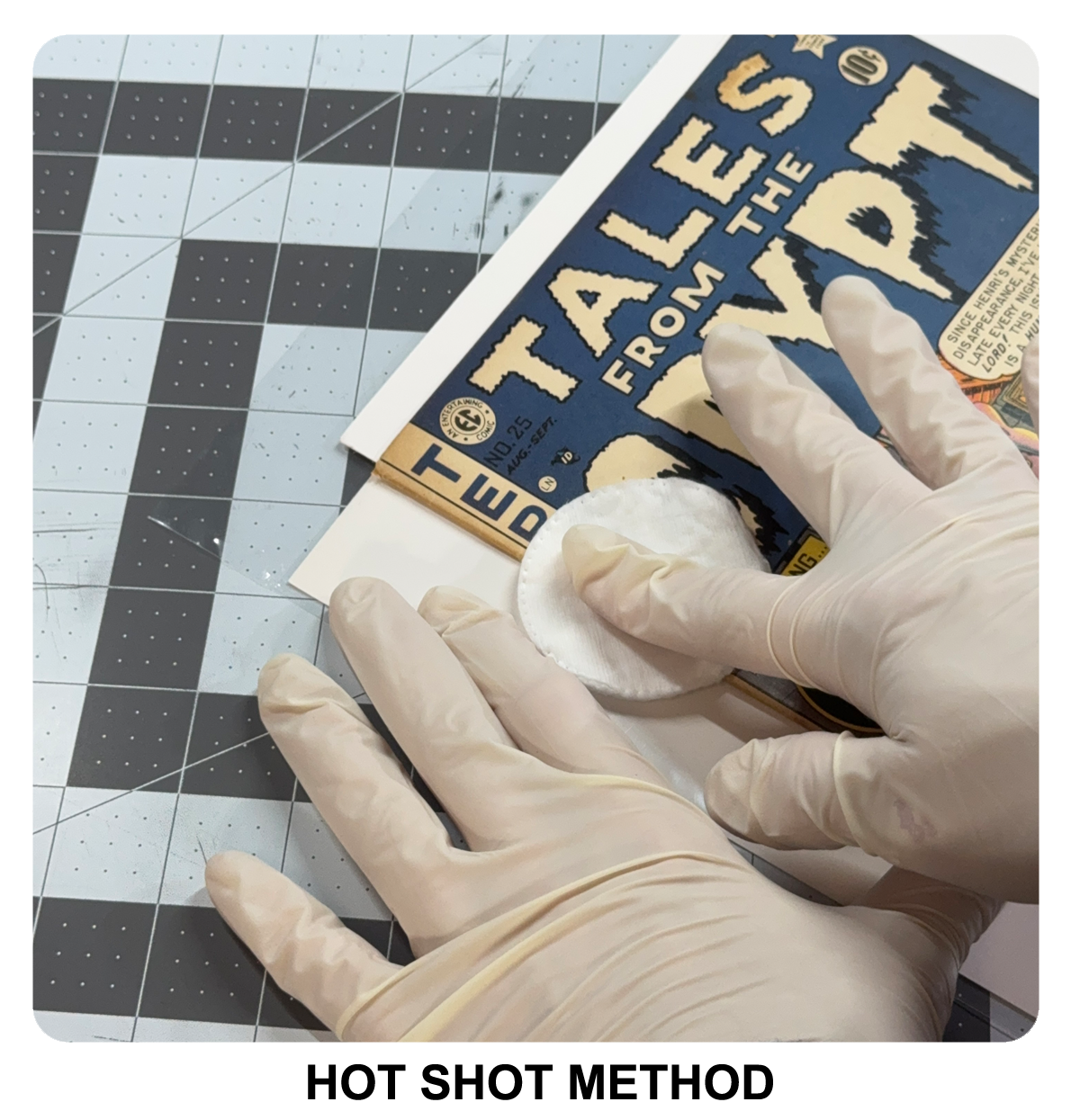

to covers, proceed with Hot Shot method (a

damp cotton round, squeezed out between 2 dry cotton rounds)

on any localized areas that require additional humidity. No

Hot Shots to any book with thin glossy interior pages. Only

light steam should be applied using a Cut Out backer board

to modern books with glossy thin interior pages.

9. Follow all stacking layer instructions

from the provided free Basic Press stacking formula. If a

comic book has a shredded spine or spine splits greater than

1/8", place the 65lb cardstock paper 2 pages back from

both front and rear cover. If there are any inserts present,

place a sheet of 65 lb cardstock before and after each insert

page. If there is a Mark Jeweler Insert with an adhesive backing

strip for the mailer envelope, place a sheet of clean SRP

Paper after the bottom centerfold backer board closest to

the insert page.

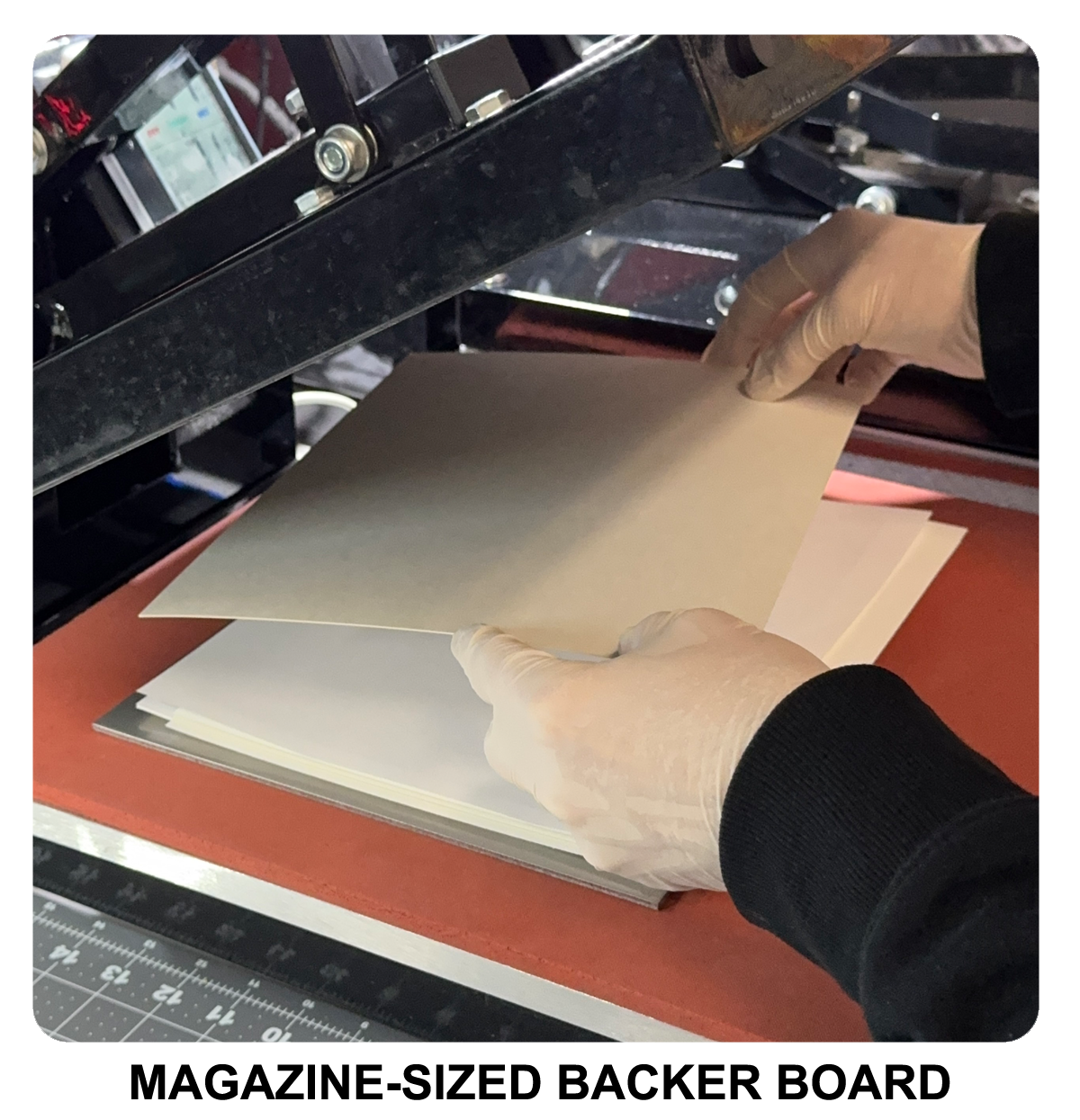

10. Place bottom magazine sized backer board

exterior layer on bottom steel plate.

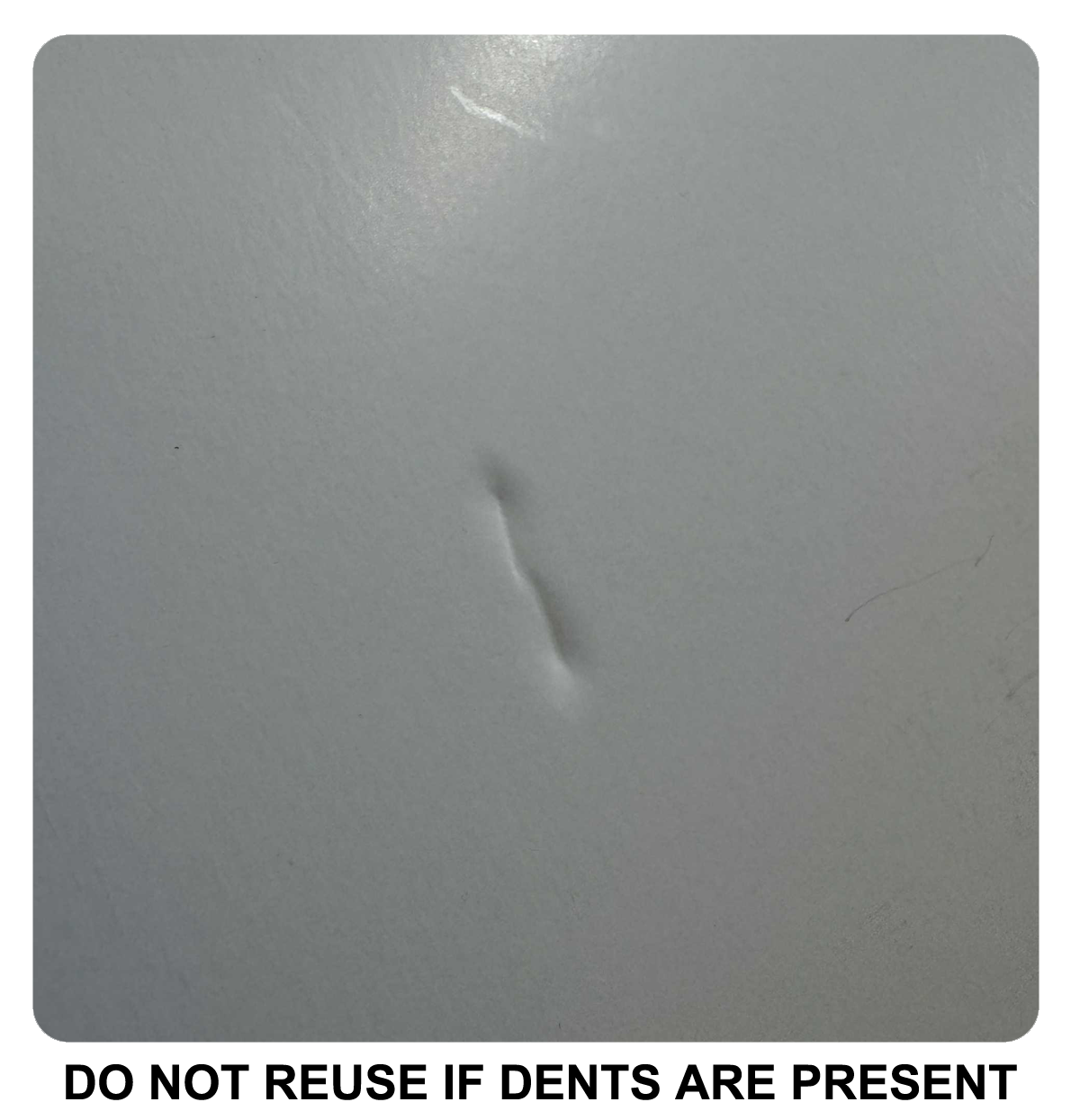

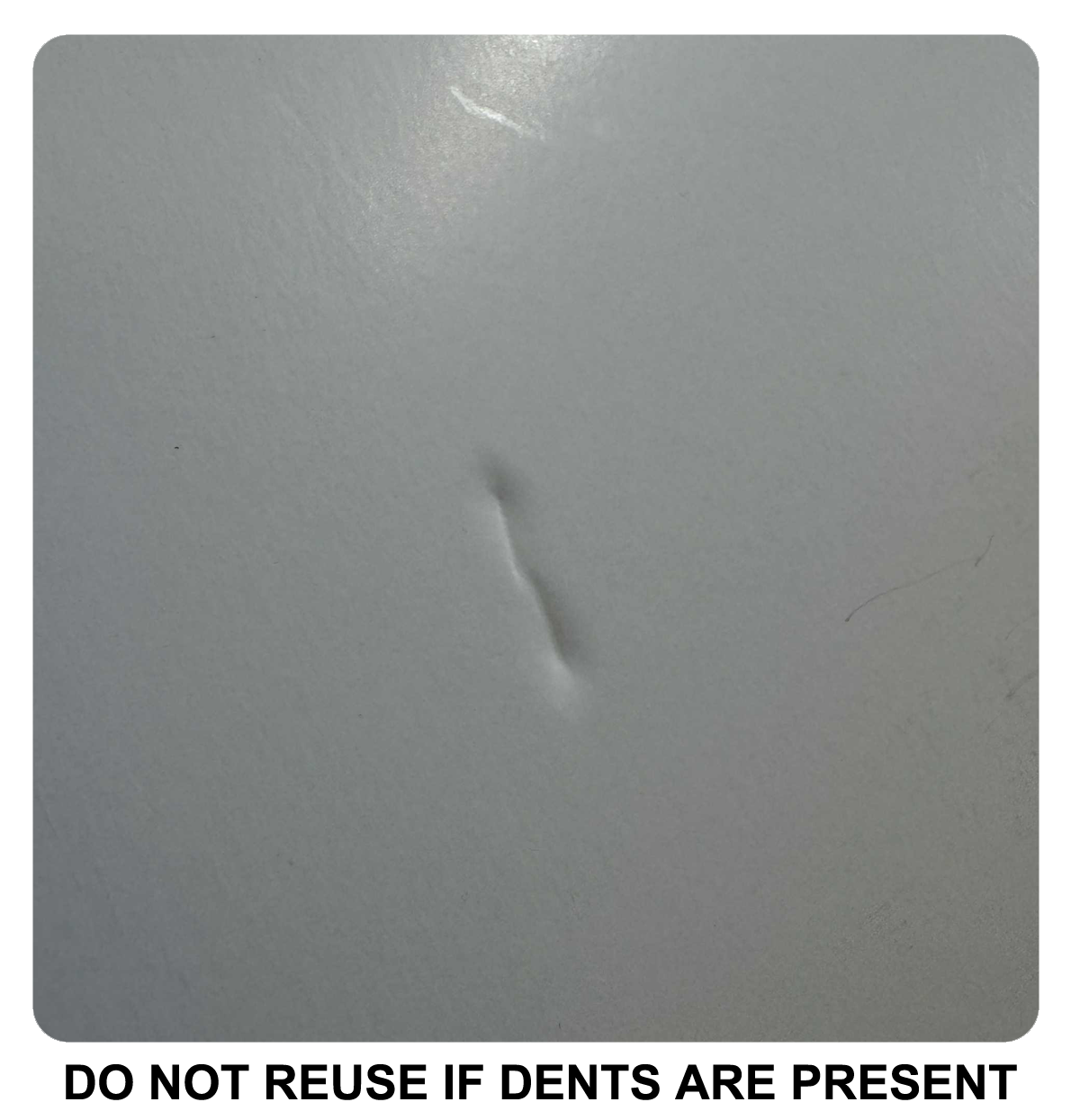

11. Do not reuse backer boards with creases,

staple dents, or dents present. Never reuse copy paper or

cardstock paper. Backer boards may be reused, but only if

there are no dents or warping present.

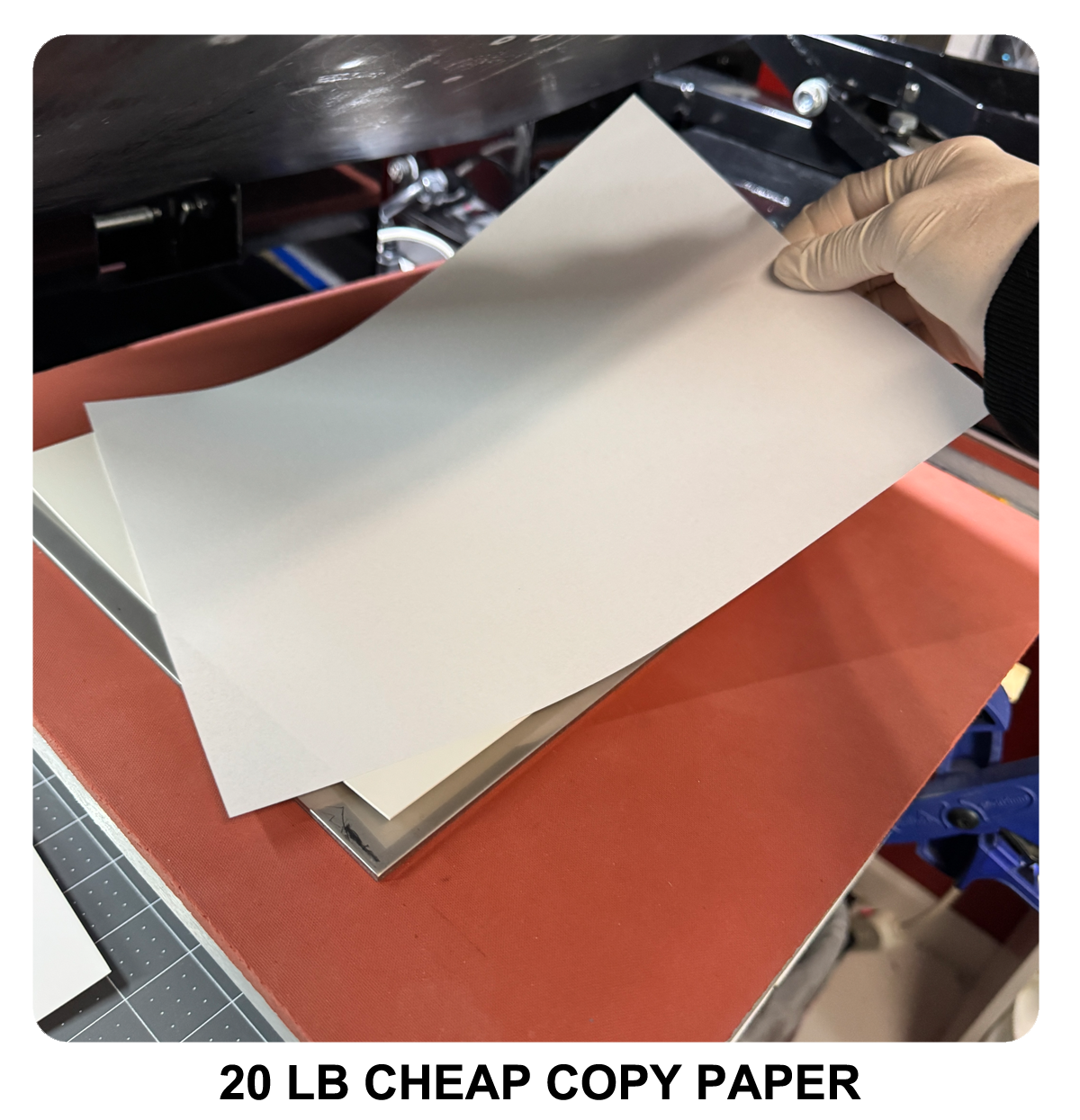

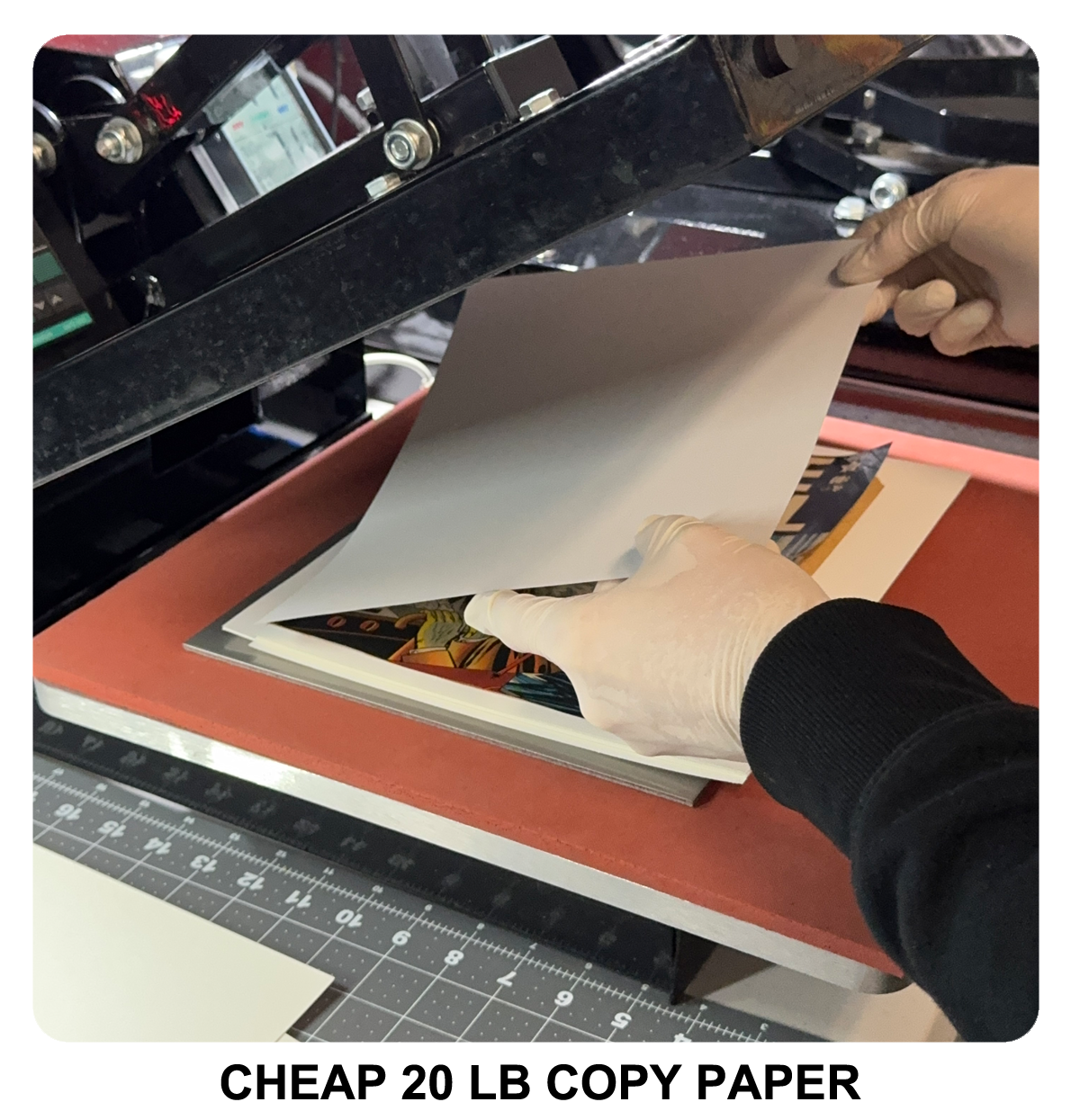

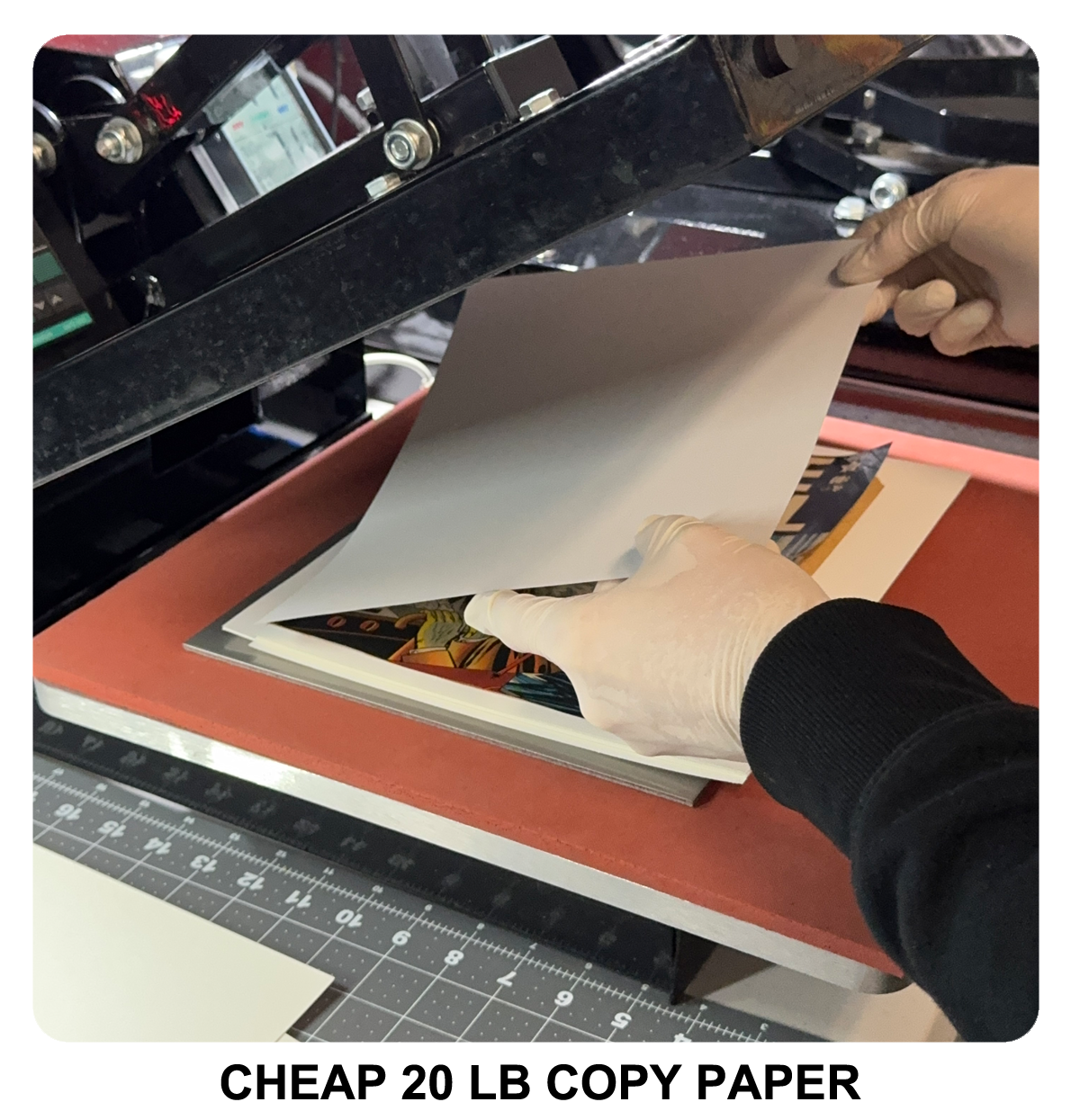

12. Place a sheet of cheap 20 lb copy paper

on bottom backer board. The cheaper the brand, the better.

Many premium high quality brands have now started to use OBA

(Optical Brightening Agents) to their paper stock, which can

cause a film or transference of these chemicals to comic books

when damp or wet. We currently recommend Amazon Basics brand

copy paper.

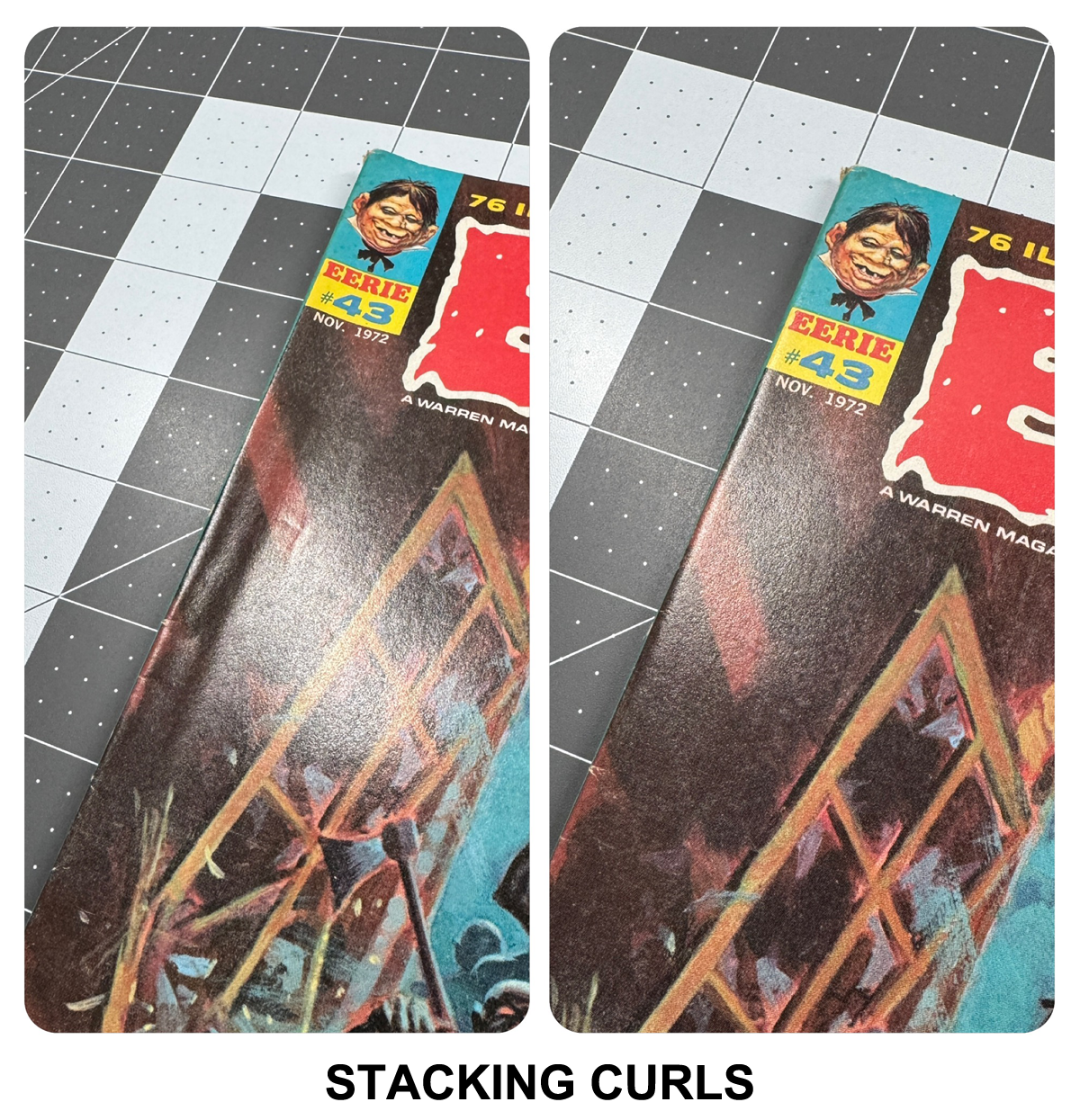

13. Special Instructions: If you are pressing

a book with a stacking curl, or over 32 pages long, or a squarebound,

place book with the most defects facing down first because

you will flip the book and repeat the heat cycle to the other

side after Step #20. Stacking curls should start with the

bend facing up on the first press before the flip.

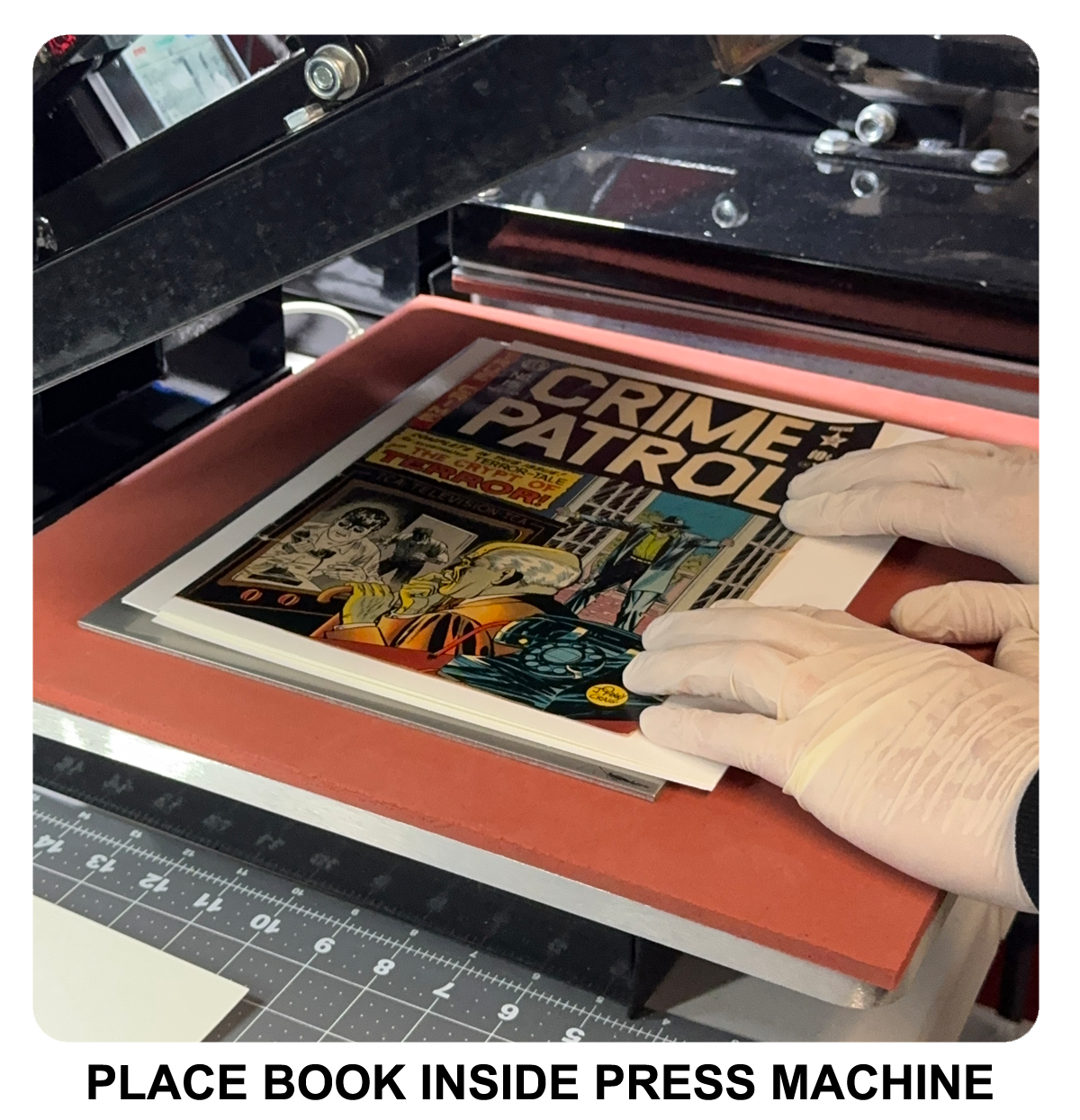

14. Place book with stacking layers in press

machine. Spines should be positioned parallel to hinge or

arm of machine. Book stack should be centered on plate.

15. Place top sheet of 20 lb copy paper on

top of placed book with stacking layers.

16. Place top magazine sized backer board exterior

layer on top of copy paper layer.

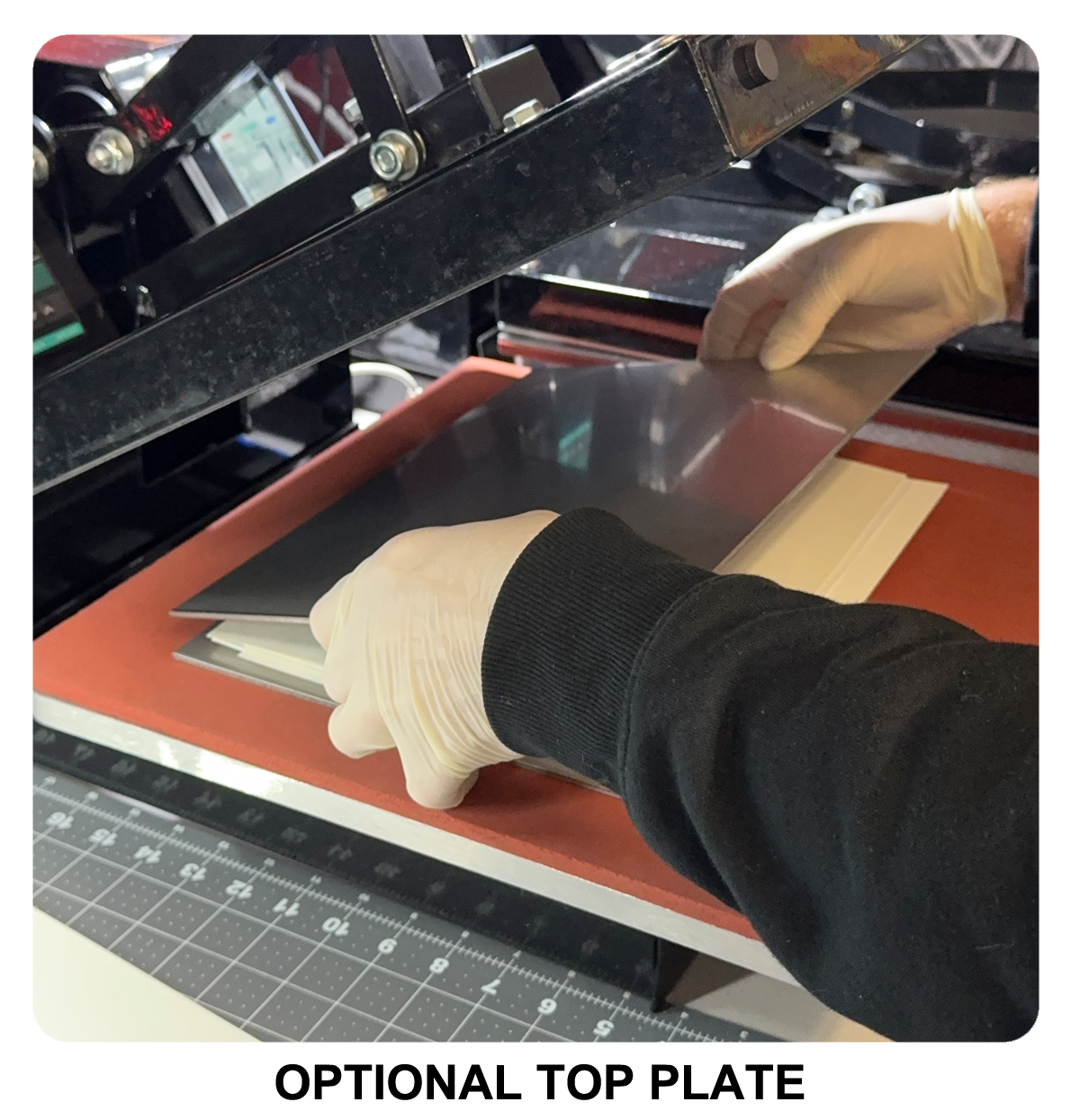

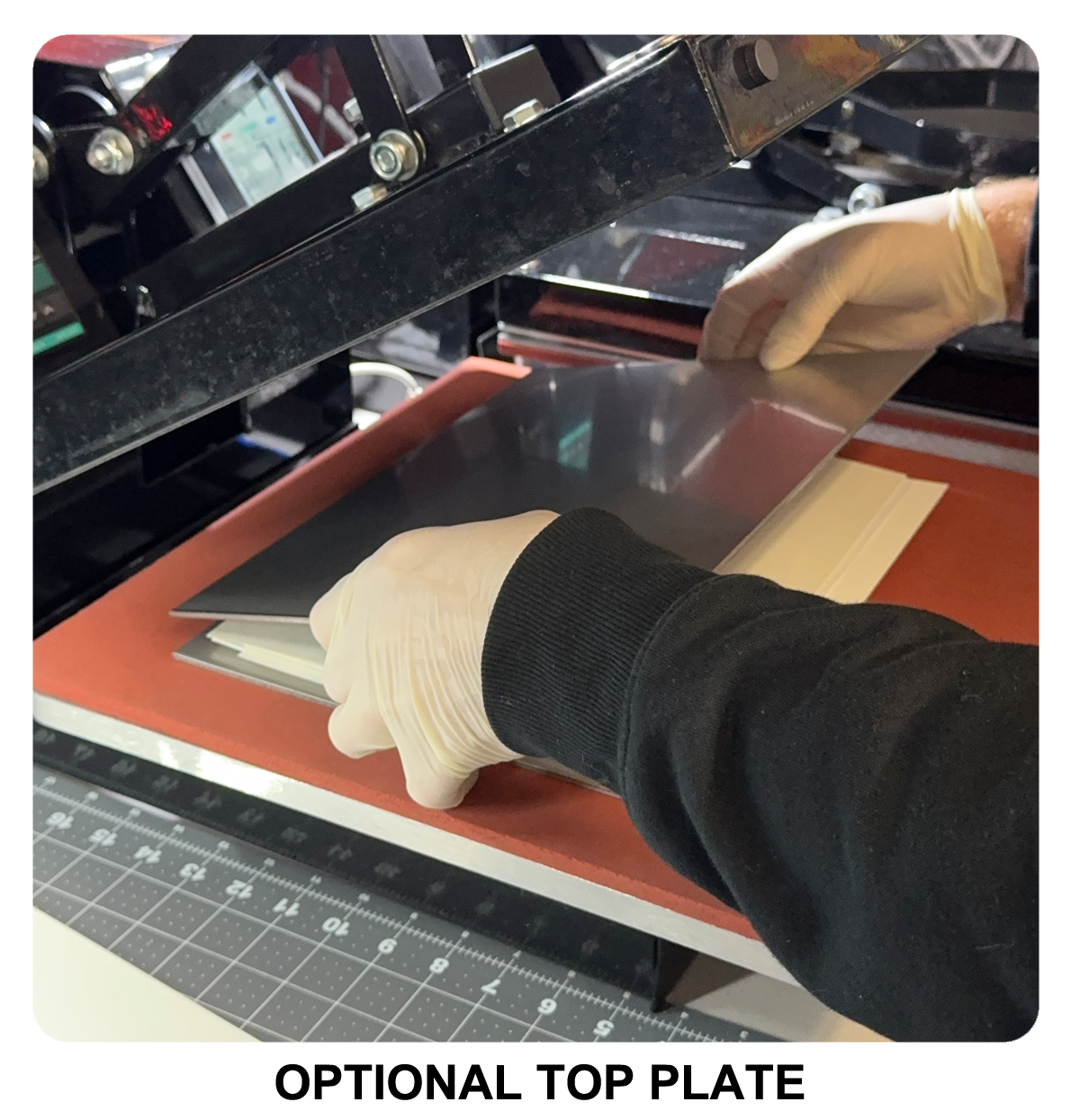

17. Place optional top plate on top of top

exterior backer board, if you use one. I personally use a

top plate to help keep all the stacking layers in place. Others

find the top plate redundant.

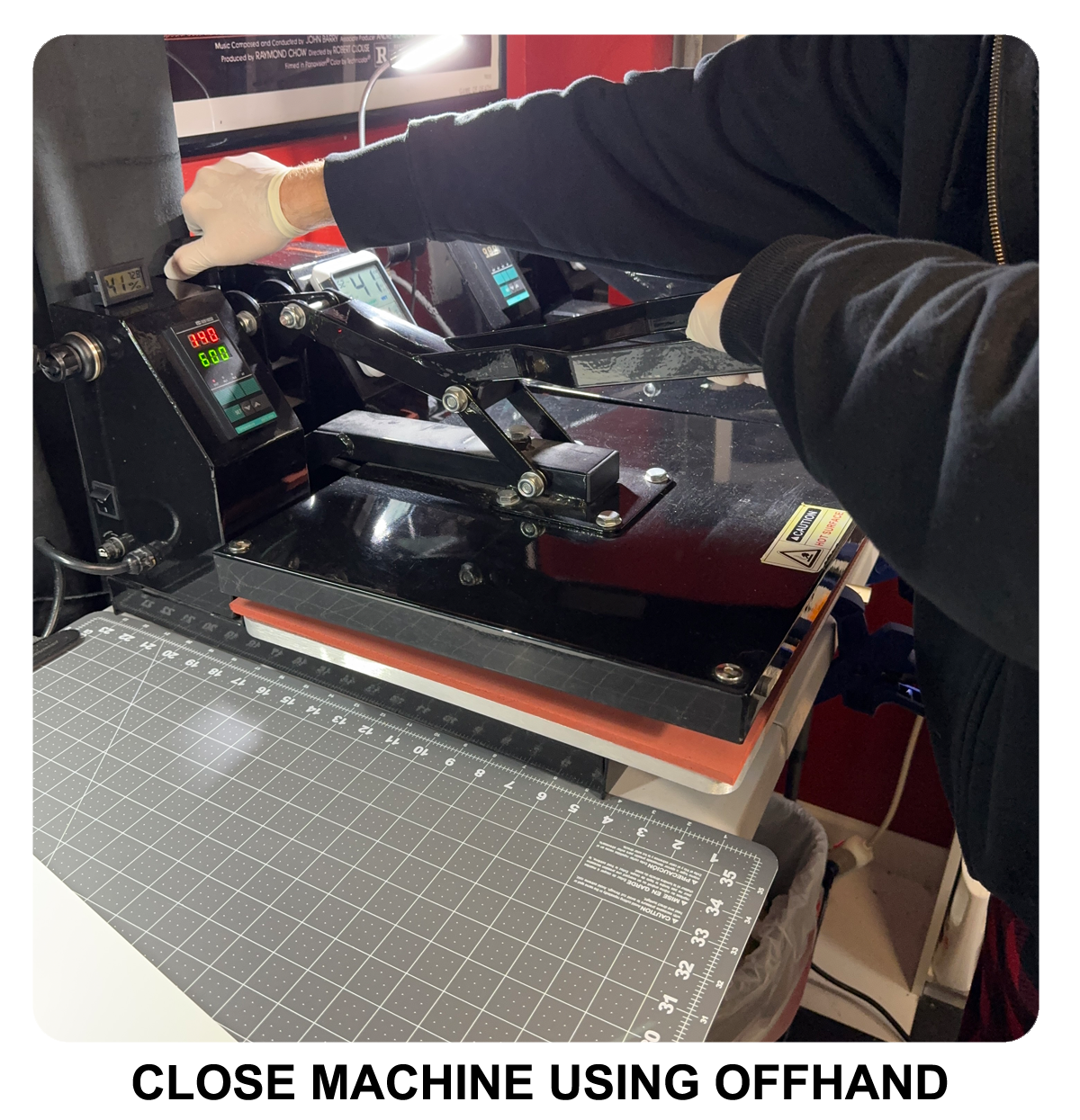

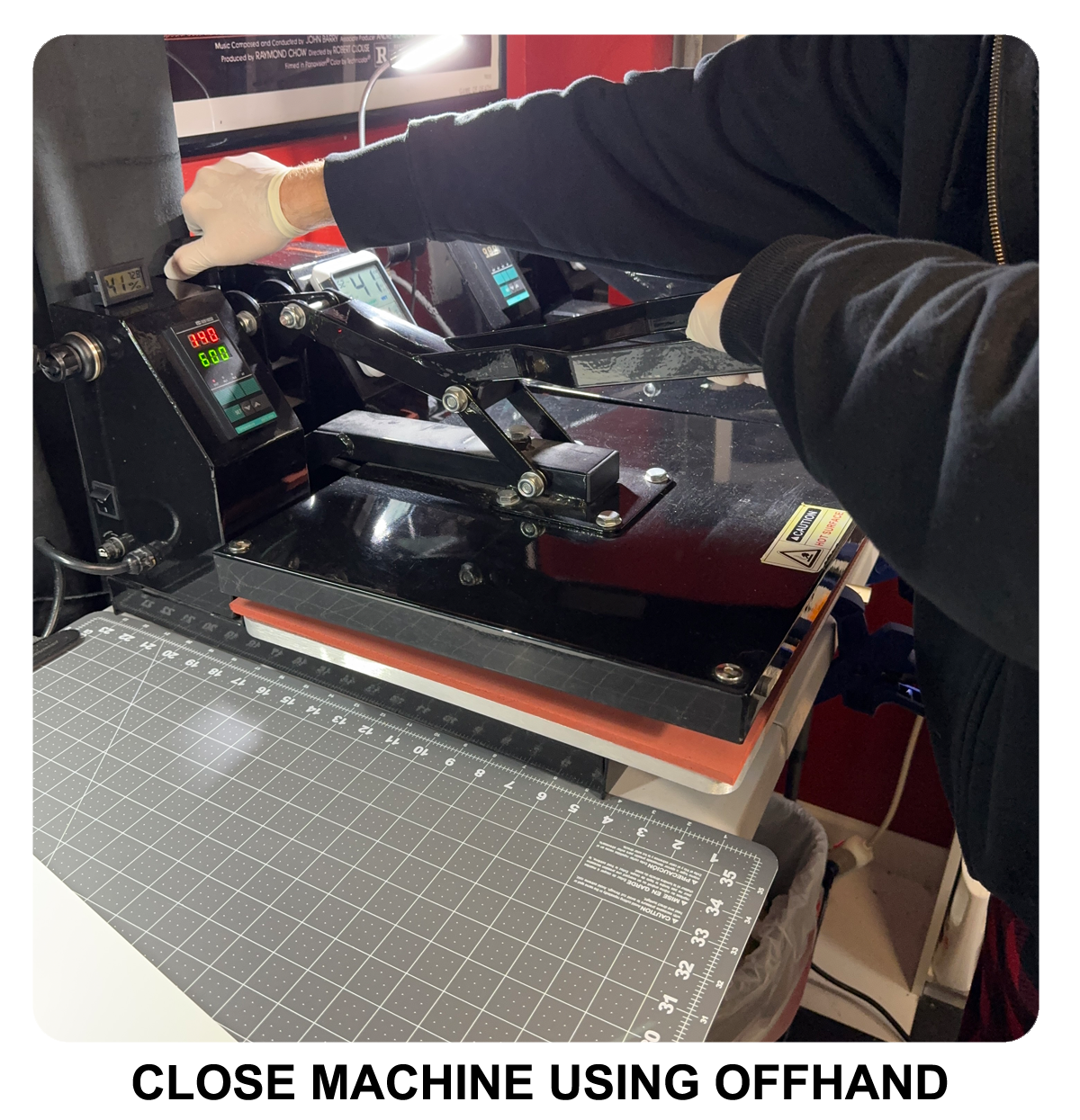

18. Adjust pressure with your main hand if

needed. Close press machine using off hand.

This ensures that you don't accidently close the press machine

using too much force and pressure. If you cannot close the

machine using your off hand, you are using too much

pressure.

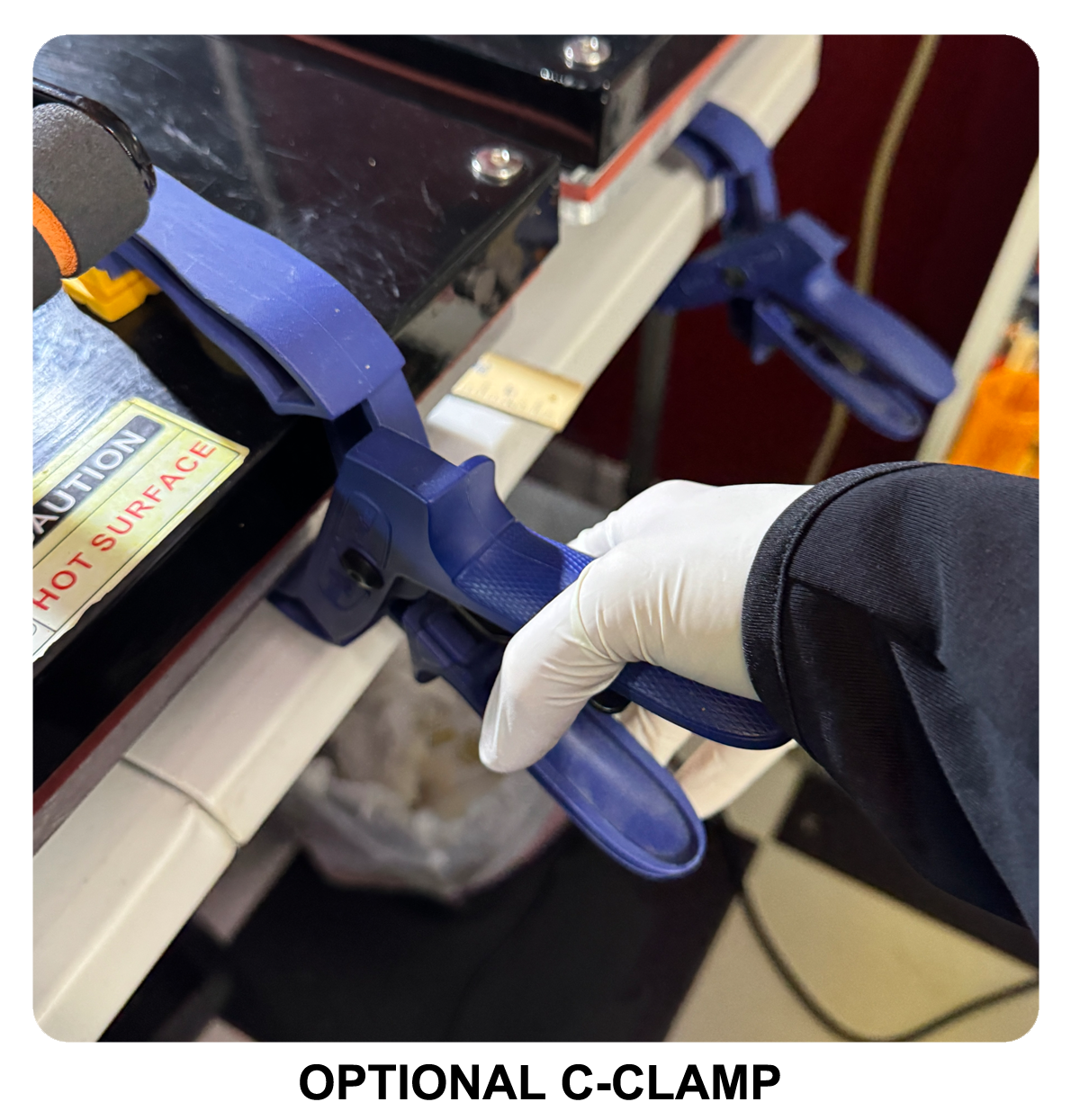

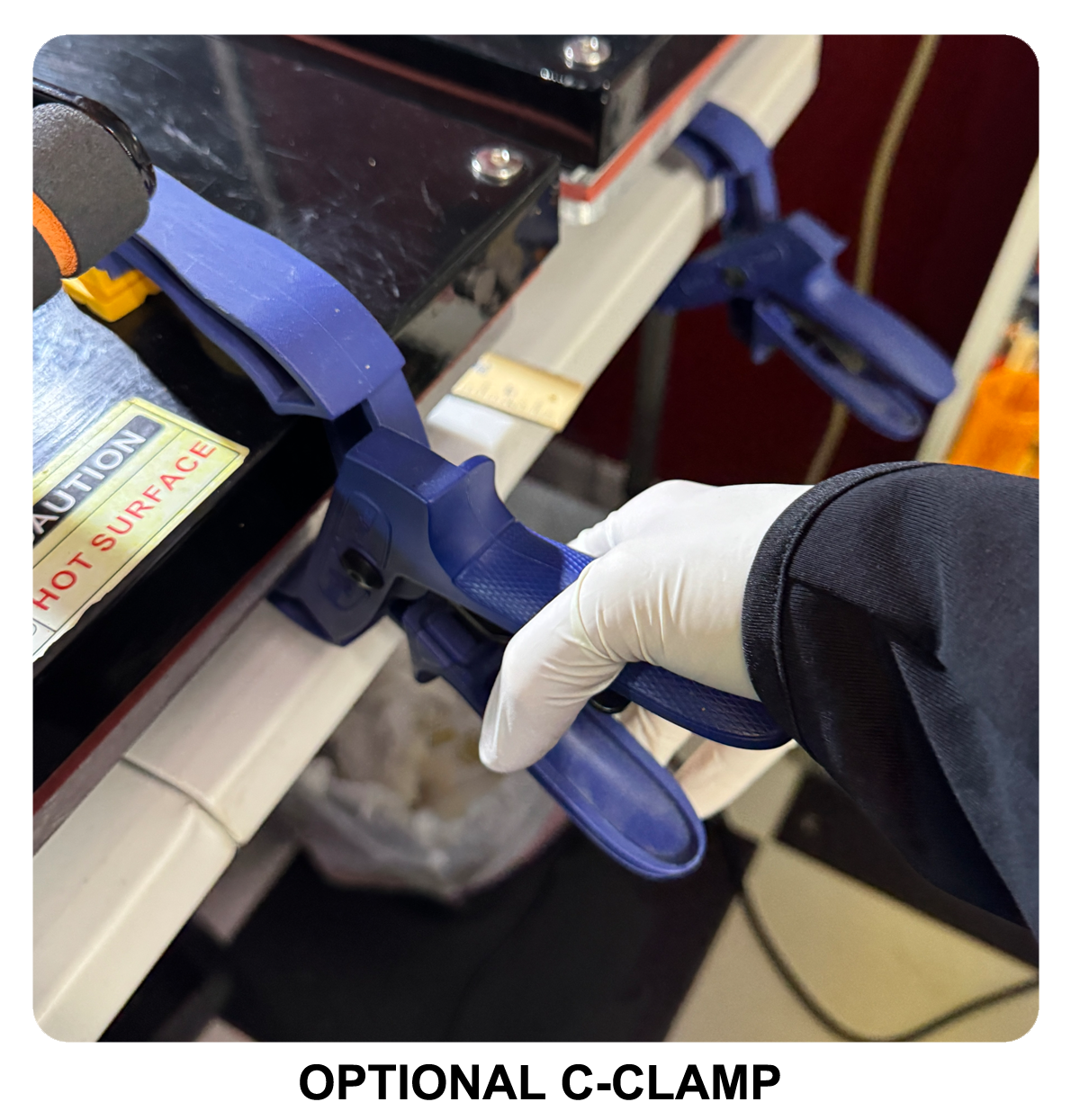

19. Use an optional C-Clamp on the front

edge of clamshell press machine if you have one. Using a C-Clamp

will help make the downward pressure more centralized as opposed

to being from the inside of hinge.

20. Leave heat cycle ON. Wait for the recommended duration

of the heat cycle to complete.

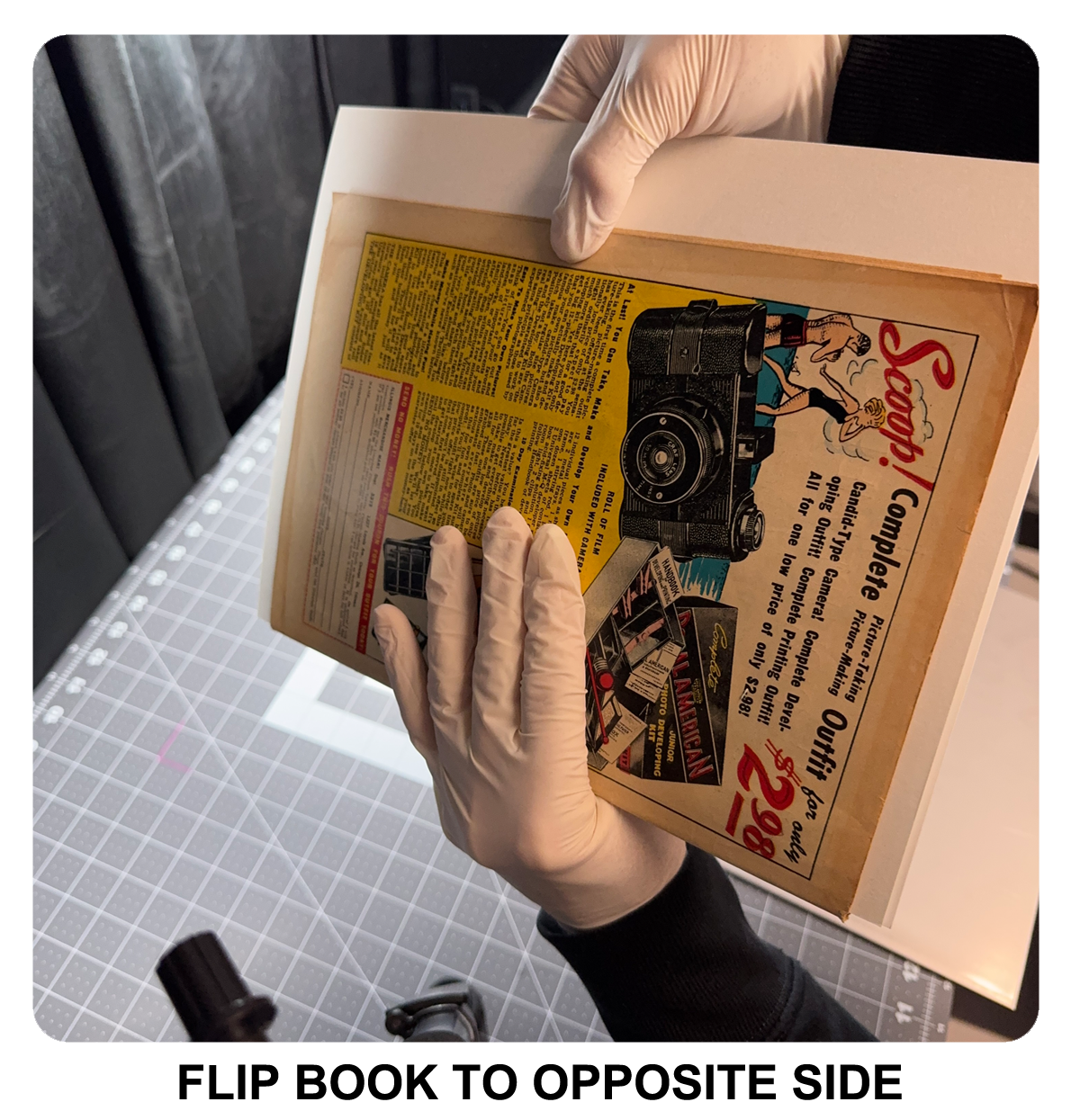

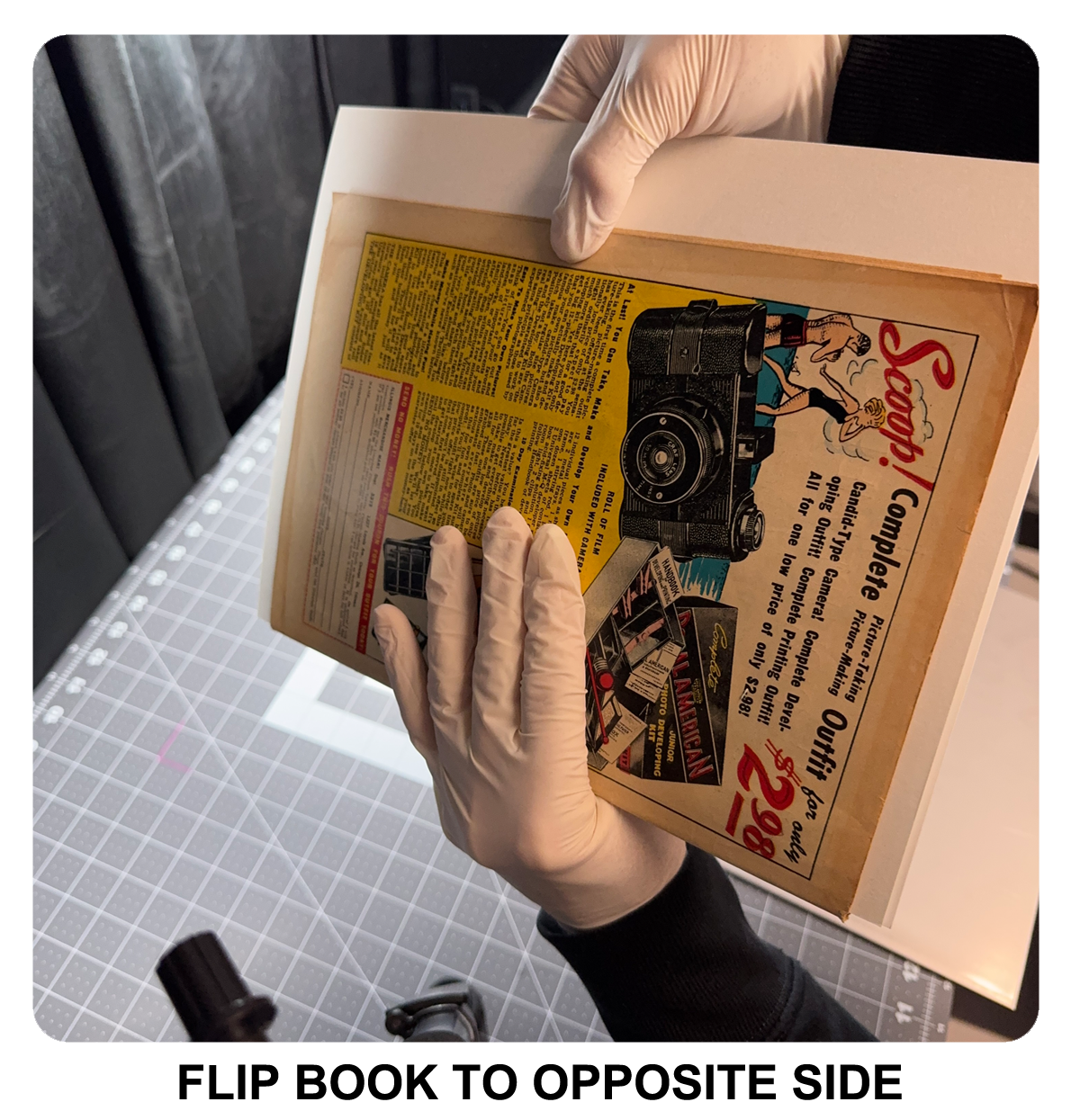

21. Special Instructions: For thick books

over 32 pages, squarebounds, giant size, or stacking curls,

flip book to opposite side with the most

defects facing up and repeat steps #3 - #20. You would also

flip a book if there are a ton of defects present on both

sides. If none of these conditions apply, leave the regular

sized 32 page comic book inside press machine and

do not flip.

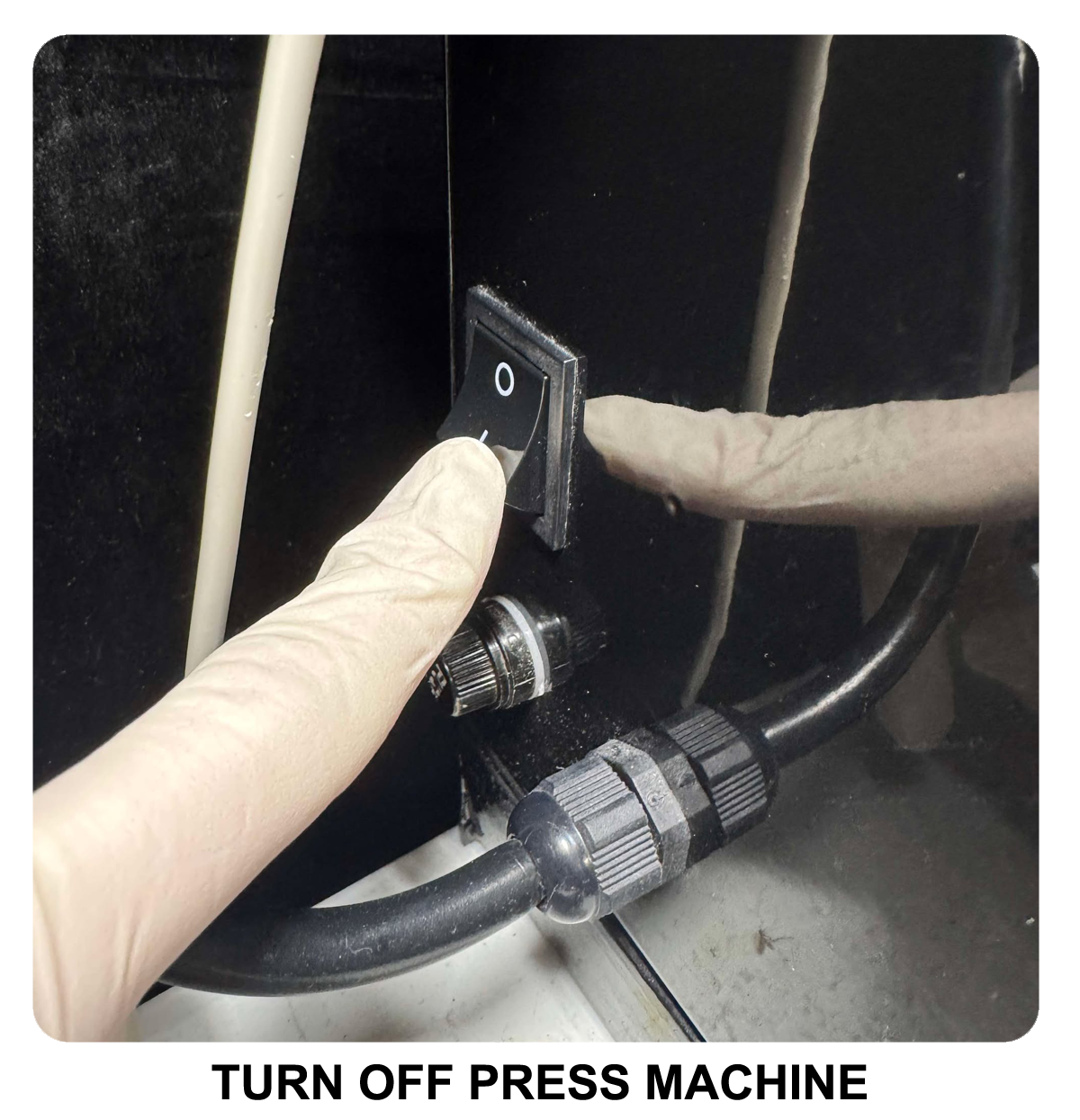

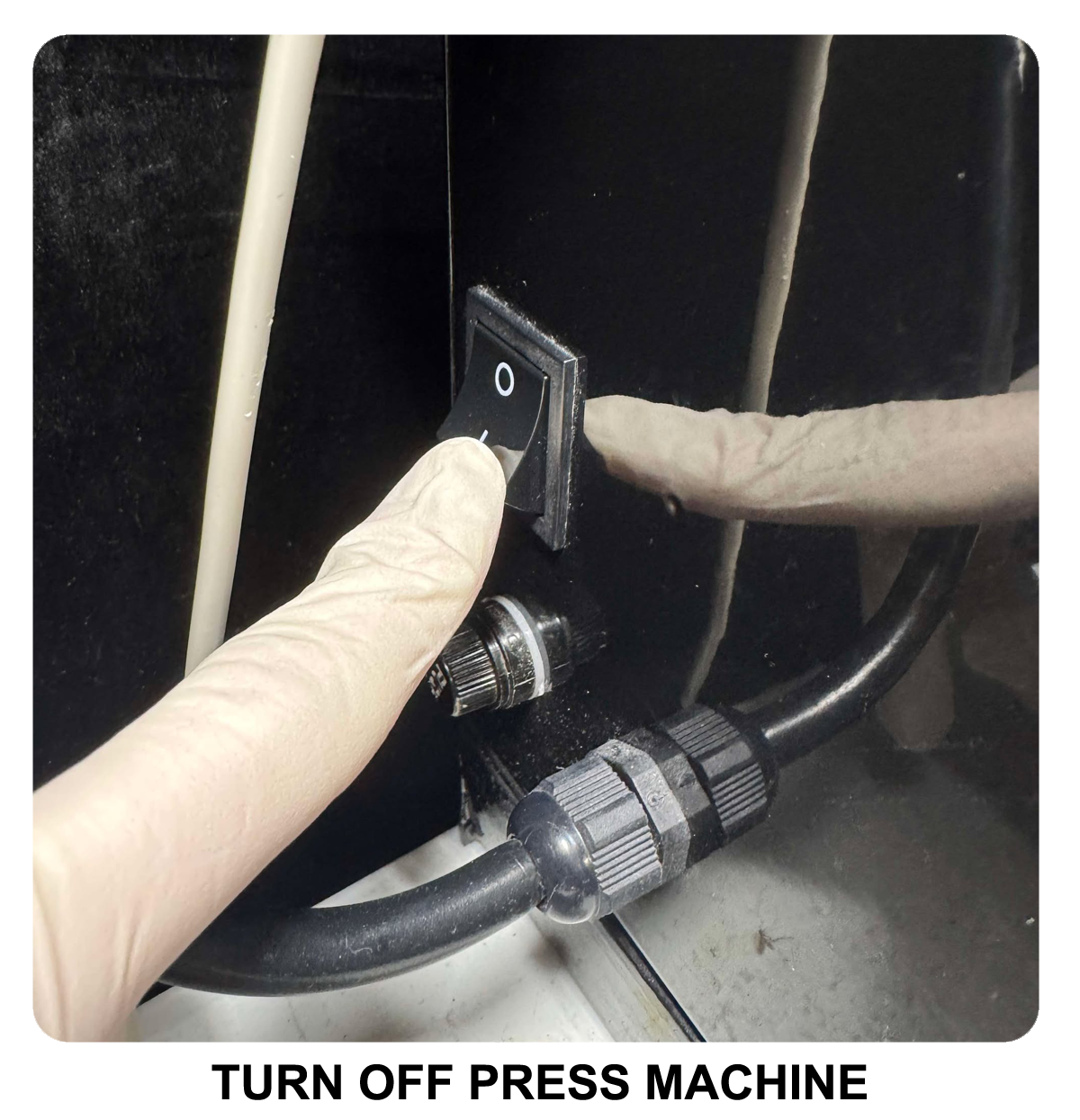

22. Once the heat cycle is complete, turn OFF press

machine. Do not open press machine right now. There

must be a proper cool-down period or defects are guaranteed

to return (reversion).

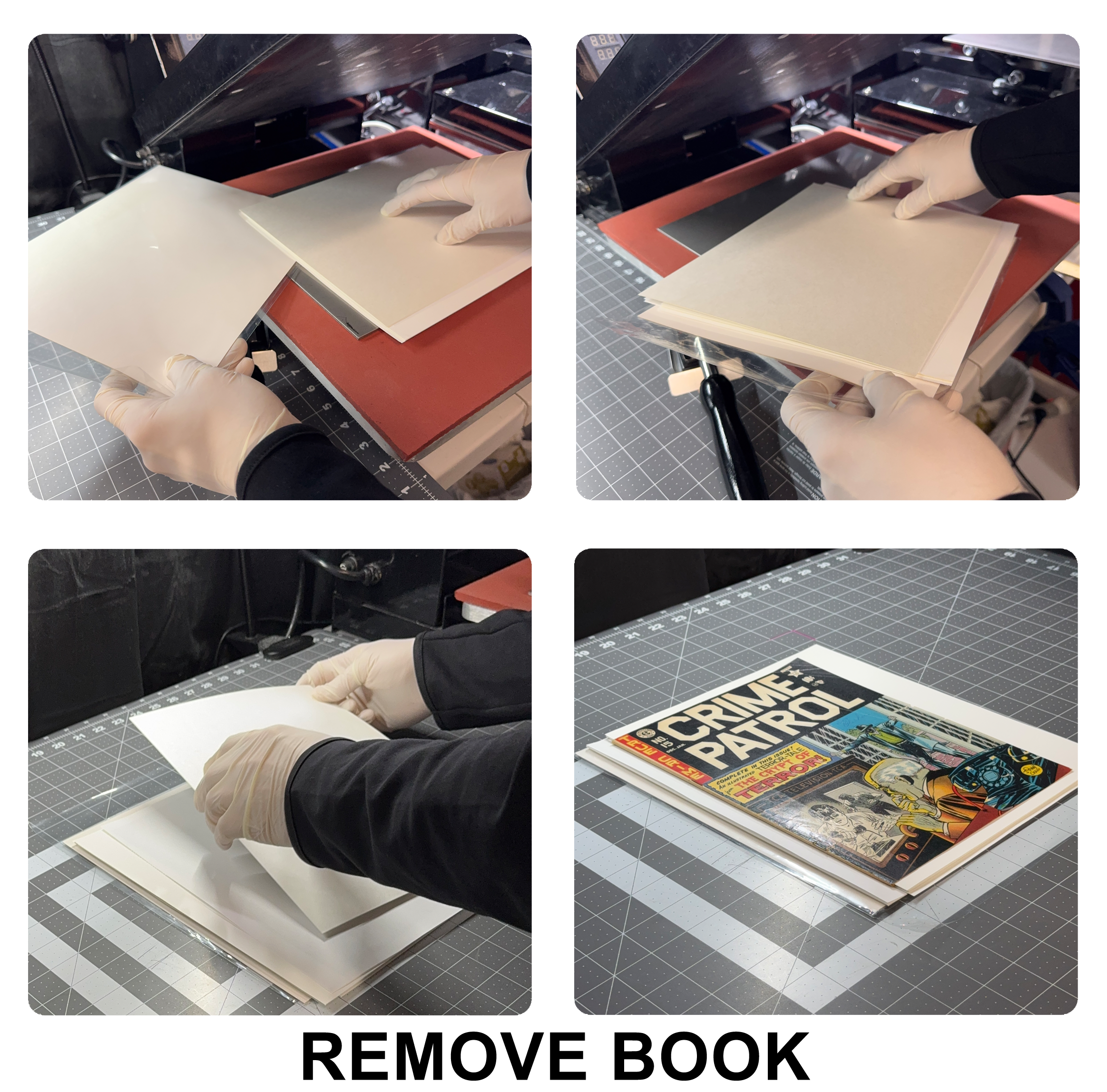

23. For vintage comic books and magazines with flat matte

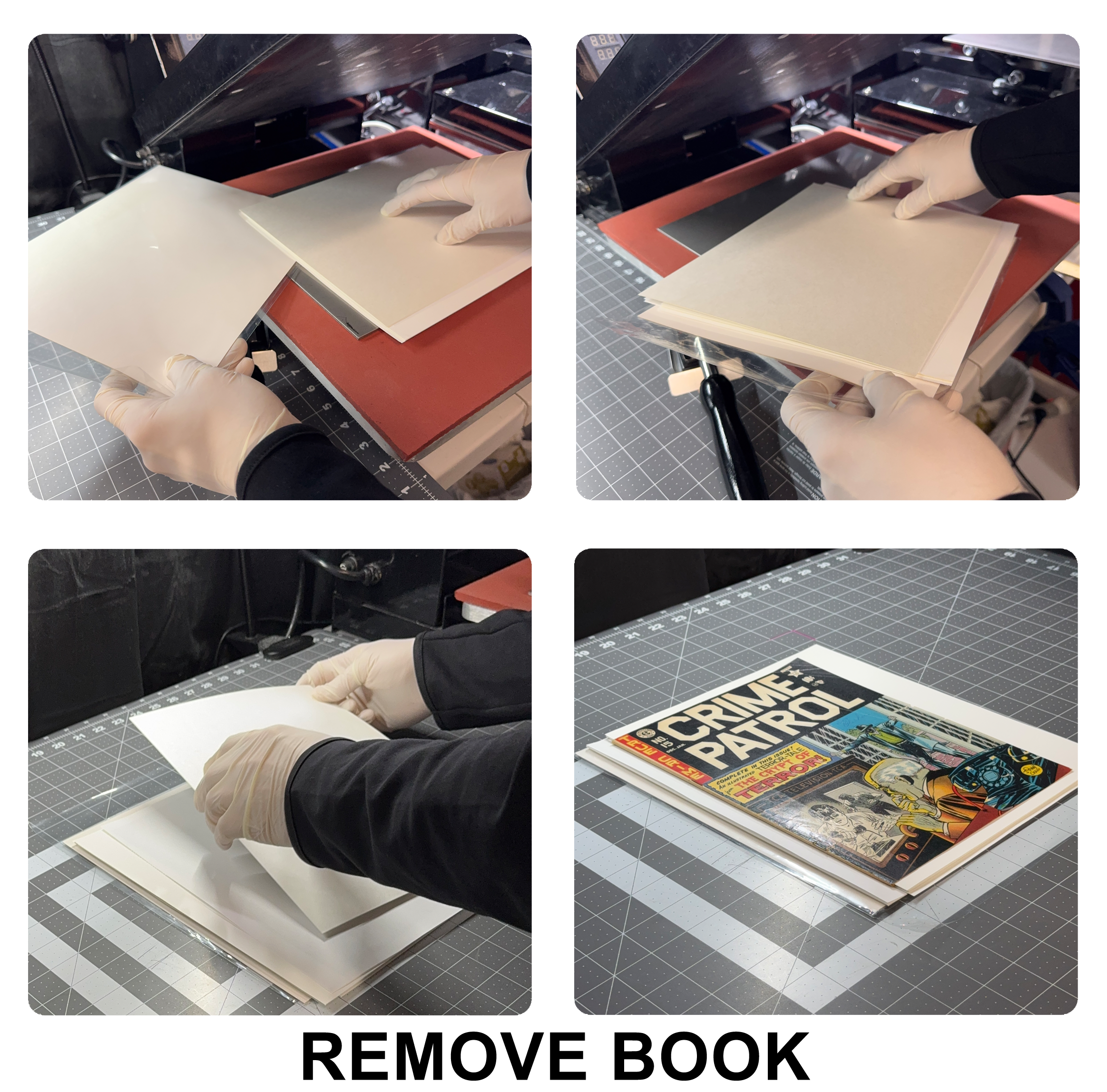

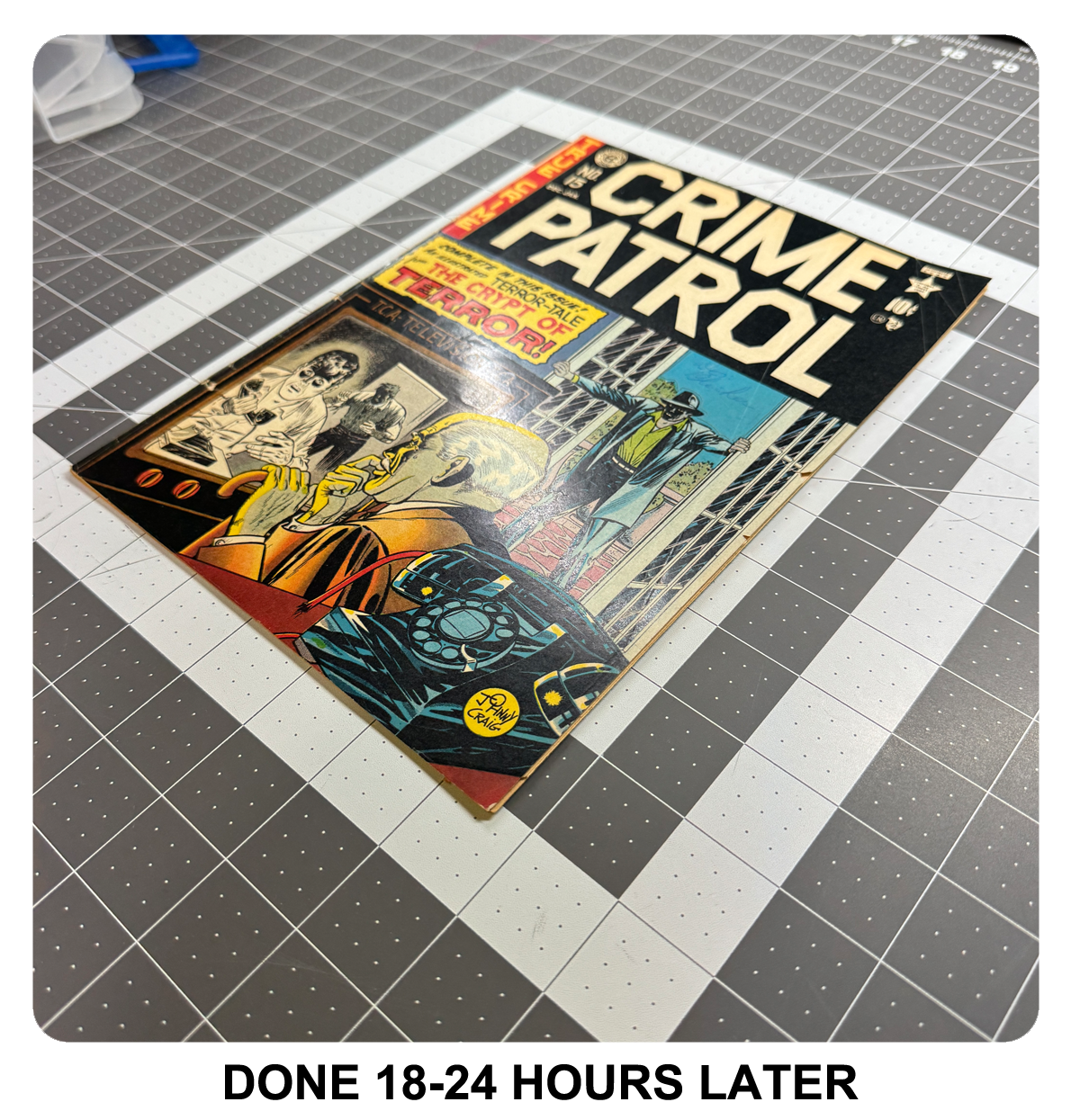

interior pages, wait 18-24 hours before removing

book from press machine. For all books with thin glossy magazine

style interior pages, wait 2-4 hours before

removing book from press machine. Waiting is equally important

as the press itself in order to produce the best results.

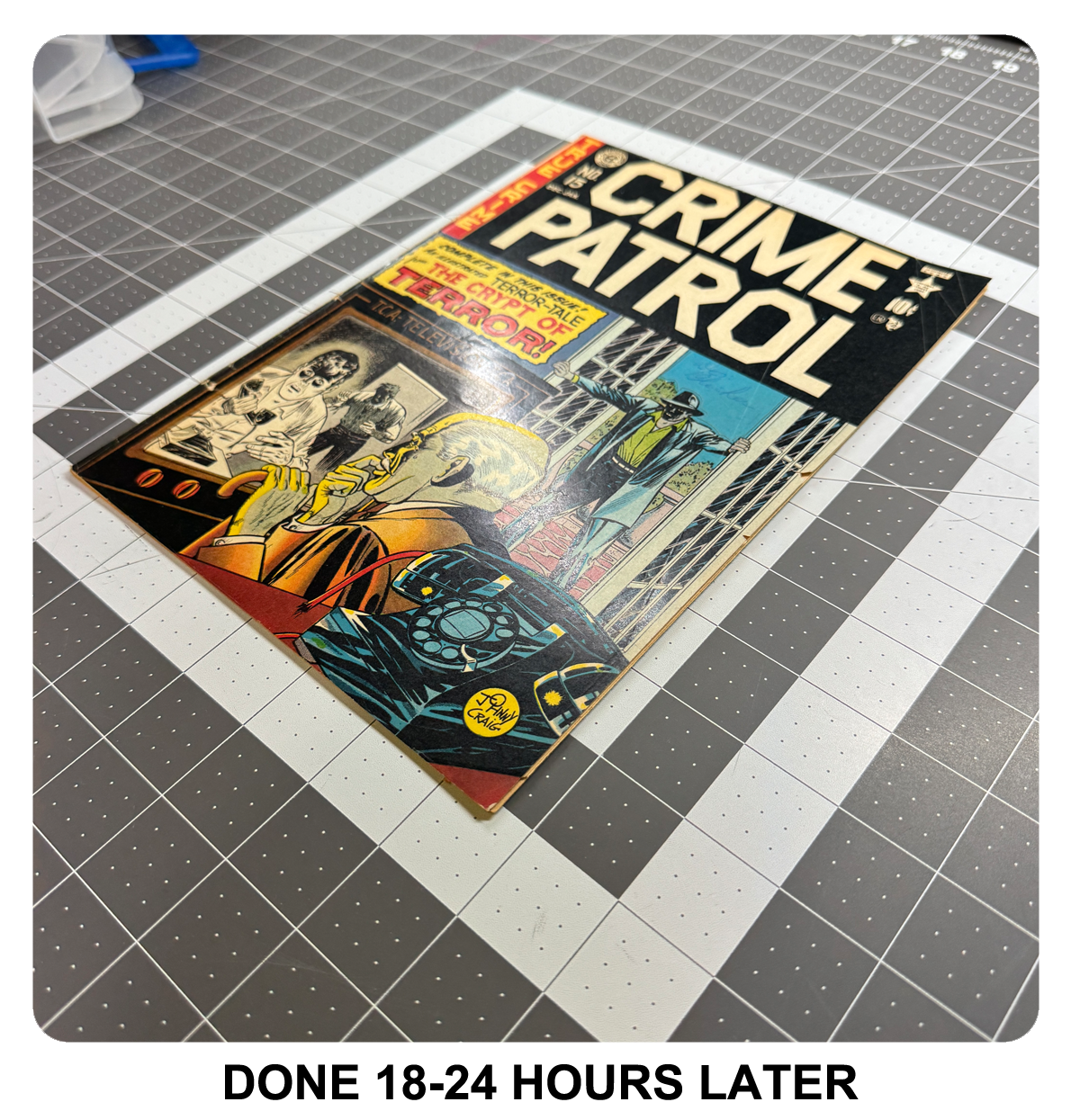

24. Books are typically done the next day.

Keep pressed books in the same room as the pressing room environment

for at least 5-7 days. Perform a reversion inspection check

and take new photos. Compare results. After 7 days, the book

can be safely shipped off to a third-party grading company

or client.

Post-Press Storage Guidelines

After pressing, the paper fibers of a comic are in a “reset”

state. They’ve been relaxed and flattened by heat and pressure,

but they need time in a stable environment to fully settle.

If you rush a book straight to grading or toss it back into

an unstable storage space, you risk defects slowly returning.

Here’s what we recommend:

• Cooling/Settling Period: Let

your freshly pressed book rest for at least 24–48 hours in

a controlled environment before bagging and boarding. This

allows the paper fibers to stabilize naturally at room conditions.

Some advanced pressers give high-value books a full 3–5 days

before handling or shipping.

• Environment: Keep the

book in a 70–75°F room with 40–50% RH (same as your pressing

setup). Avoid humid basements, hot attics, or rooms with fluctuating

air conditions. Stability is the key to preventing reversion.

• Flat, Supported Storage: Store

the comic flat between clean, dry backing boards (no pressure,

just support) or inside a bag and board with a full-size backer.

Some collectors stack a light, even weight (like another flat

board) on top to encourage the book to stay flat while it

settles.

• Avoid Immediate Shipment: Mailing

right after pressing is risky — comics can be exposed to heat,

humidity, or pressure during transit, which may undo your

work. Waiting a few days before packaging helps the fibers

“remember” their pressed state.

• Longer Holds for Problem Books:

If the comic had severe waves, stacking curls, or stubborn

dents, give it a bit more rest — up to a week — before grading.

Patience here means better long-term results.

General Rule of Thumb:

• Simple press (minor bends/waves):

Wait 2–3 days.

• Heavy press (major ripples/curls):

Wait 5–7 days.

• Always ship in stable climate:

Avoid mailing during extreme hot or humid weather

if possible.

REVERSION AFTER PRESSING

Another important concept is reversion — this happens when

a book looks great right after pressing but slowly begins

to “bounce back” to its previous shape. Reversion is often

caused by pressing in unstable conditions where the temperature

or humidity fluctuates. A consistent environment ensures

that when the fibers are reset during pressing, they stay

that way. Leave all vintage comic books (1930-2001) inside

press machine until the next day before removing. Flaring,

lifting, and wavy pages can develop when a book is removed

too soon or improperly stored. While rare, reversion can

(and does) happen. Review and verify the comic book retained

a good press after 5-7 days. Keep pressed

books in the same pressing room environment. I recommend

this step especially if you are pressing a book for a client,

friend, or a grading company! It is entirely possible to

come back several weeks later - only to find your hard work

performed on the book has reverted back to its previous

state. Some books can be stubborn.

YOUTUBE TUTORIAL

VIDEO PLAYLIST

I recently started some tutorial videos that illustrate different

methods and techniques covered on this page. The videos do

not have audio or sound and are shot with a gopro camera in

1080p. I don't want to be that guy, but they take a really

long time to produce and edit so, "Please give a like

and subscribe" Thanks!

How

to Press Comic Books Playlist by KaptainMyke on Youtube

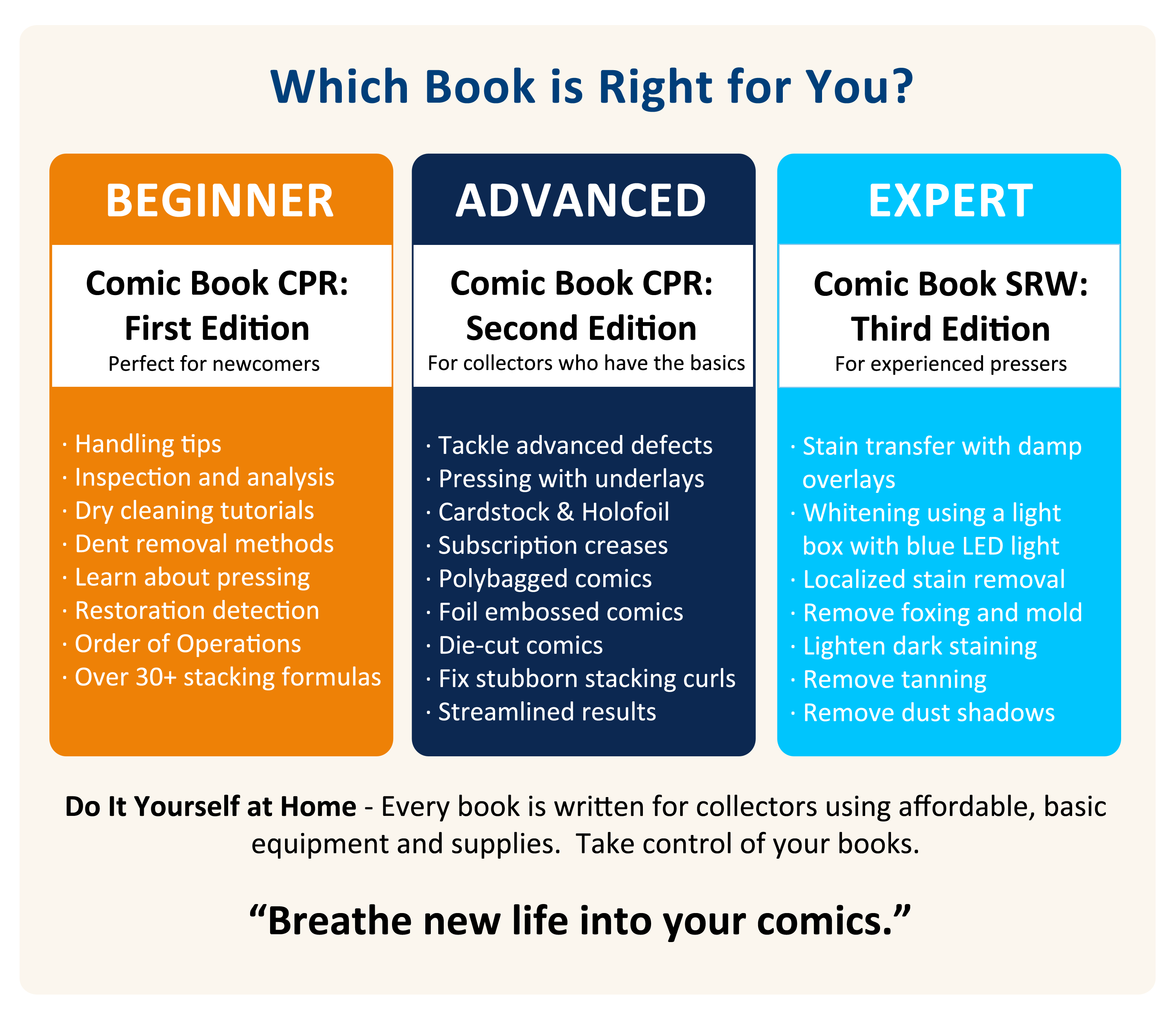

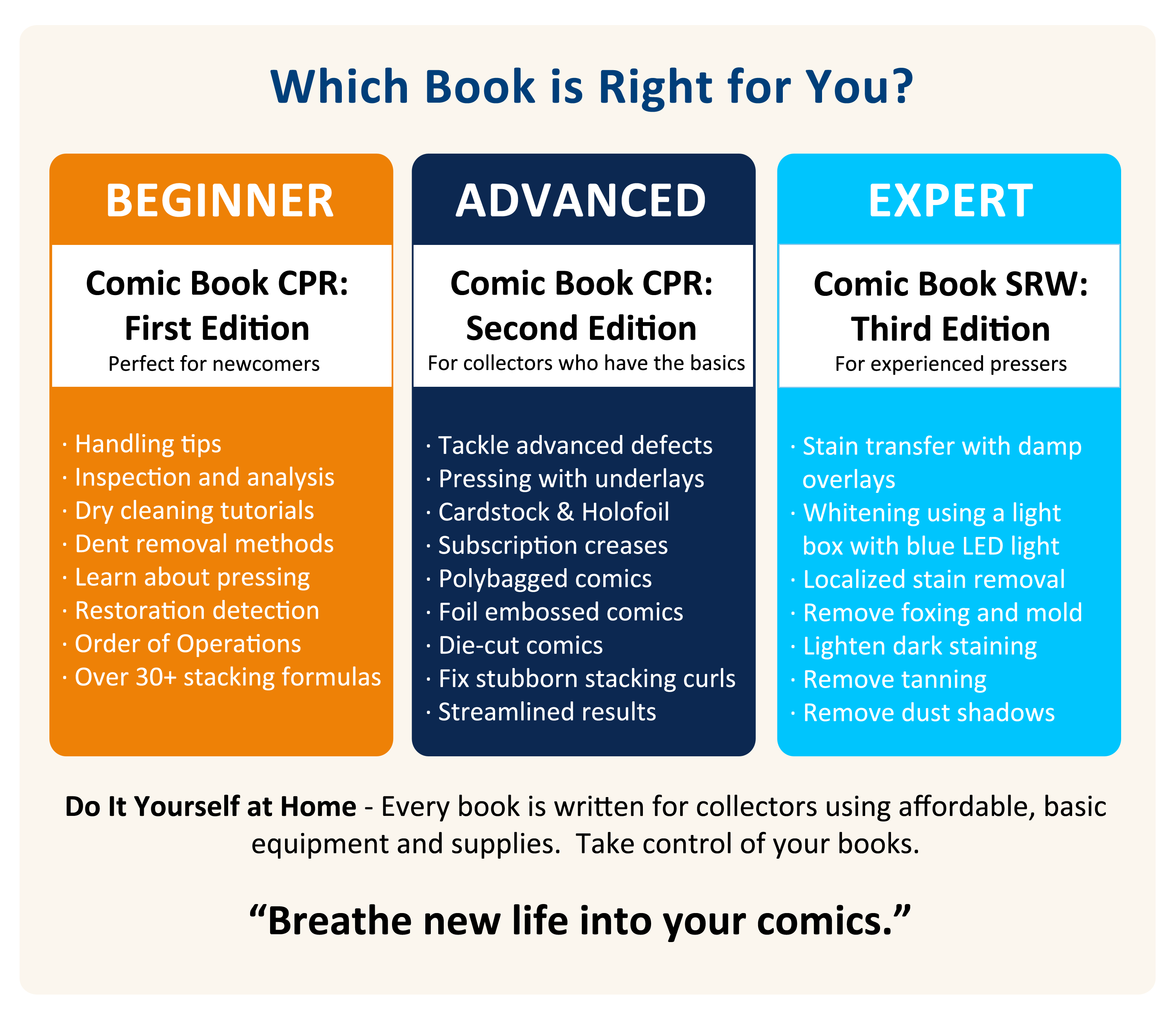

ADVANCED

PRESSING METHODS

You have read my free guide which covers everything you need

to know in order to get started pressing comics. However,

there are many advanced topics and advanced methods not covered

in this free online guide. What about restoration detection

or how to press squarebound prestige format comics? Comic

Book CPR answers all of those questions and more.

www.comicbookcpr.com.

CGC COMICS

The author is also an authorized and licensed CGC Dealer.

Have peace and mind the advice given on this website will

help you achieve the absolute highest grades possible with

CGC. CGC is the most trusted authority on third party grading

of comic books since 2000.

JOIN US

There is a dedicated Facebook Group called "KaptainMyke

Comic Book Pressing" for anyone to join and contribute

ideas open for discussion. Ask questions about this guide

or show off your own books! Anyone is welcome to join. I firmly

believe the spread of accurate free information will help

us all keep books preserved and conserved. You may find the

Facebook Group at this link here:

https://www.facebook.com/groups/kaptainmykecomicpressing

CONCLUSION

The overall goal of this guide is simple: Press books in a

manner so that others cannot detect the book has been pressed.

Light pressure, not firm or hard pressure. Do not burn the

book, do not pop the staples, and do not spin the books on

surfaces. For temperatures, 150-160 degrees or lower seems

to be the “sweet spot” on most books to play it safe. Pressing

under high heat for less than 5-7 minutes on each side is

good for most books. Keep moisture and humidity to a minimum

on your books. Always keep a timer with you and don’t forget

to set your timer! These steps are some of the things that

can be done to successfully press a comic book, magazine,

or poster with minimal to no damage to the item being pressed.

These tips will hopefully save you money,

and guide you along the way as YOU learn and pick up new ideas

and better ways to accomplish things. I am not a professional

presser, and I’m not a professional grader. However, these

are the methods I use when I press comic books as a hobbyist.

All of this is a learning process. I encourage

you all to share your ideas among everyone so that we can

all prevent damage to one another’s books. I am open to any

feedback and suggestions. I also reside in a coastal Northwestern

state, which is more humid than inland states. Your results

may vary based on humidity and temperature of the climate

you reside in.

Shareable Links:

Thank you!

KaptainMyke

|