USING THE RIGHT PRESSURE

I tell people to use the adjustment knob with your main

hand, and clamp or handle of press machine use with

your weak hand. Do this method at the same time with

both hands: If you cannot close the press with your

weak hand using a limp wrist, its too much pressure

so you slightly back down the adjustment knob with your

main hand as you try to close the press with your weak

hand. If the press won't close with your weak hand,

try backing down the knob a little more counter clockwise

each time until it closes with little restraint. Otherwise,

you risk crushed staples and spines, or staple rub to

the cover. If you can see staple indentations on your

exterior paperstock stacking layer, you have used too

much pressure. Do not use the adjustment knob while

the press is in the closed and locked position. You

will strip out the shaft bolt.

LARGE STAPLES

For large staple prongs, larger staples, and mis-staples...

Use two magazine-sized backer boards at the centerfold.

Always check your backer boards for staple indentations

to see if you used too much pressure. This damage is

often permanent. Also known as "Staple Push"

- Good luck.

DIVOTS AND PEBBLING

Do not press comics using only plates. This is not ideal

- due to dust and other particles or contaminants in

the environment. The plates are sanded down from the

machining process and to wipe off lubricants from fabrication.

You should still be using an exterior stacking layer

for protection against divots, dust, and dirt particles.

Use either a magazine backer board, cardstock paper,

press board, or poster board alongside copy paper on

the outside of your books. This creates a clean, disposable

environment for comics being pressed. The plates are

a method of heat transfer, not protection against divots

and pebbling.

REUSING STACKING LAYERS ☠️

I would not recommend reusing copy paper or cardstock

paper. You are allowed to reuse backer boards if there

are no staple dents or warping present. Reusing interior

stacking layers opens the possibilities of dust, hair,

and other contaminants getting pressed into book covers...no

matter how clean you think you or your workstation is....The

"human element" of this equation is not perfect

and will often make mistakes. If you see staple indentations

on your backer boards (exterior stacking layers) then

you are using too much pressure.

WAVY BOOKS

Humidity is one of the most overlooked parts of pressing

and preserving comics, and it can make or break your

results. Paper is organic. It breathes, absorbs, and

reacts to the air around it. If your pressing room isn’t

stable, you’ll fight against nature every time you press.

A comic won’t just remember folds and creases—it will

“remember” the environment it was stored or worked on

in.

• Temperature Range (70–75°F)

The 70–75°F range is considered a sweet spot—comfortable

for you, stable for all comic books. “Comics want to

be comfortable, like people.”

o Too hot: Paper fibers become brittle over time, inks

can fade faster, and press heat has less predictability.

o Too cold: Paper stiffens and becomes less flexible,

making it harder to “relax” during pressing. Flaring

is a common side effect to a cold room.

• Humidity Range (40–50%)

At 40–50% relative humidity, the paper fibers stay flexible

without swelling—perfect for pressing.

o High humidity (above 55–60%): Paper absorbs moisture

and swells. Glossy covers can wrinkle or ripple (called

humidity waves). Mold can develop inside boxes and books.

Pressing results won’t hold—creases you flattened can

“reappear” once the paper reabsorbs moisture.

o Low humidity (below 35%): Paper dries out and becomes

brittle. Staples and inks can expand/contract differently,

causing stress marks. Waviness is a common side effect

to a low humidity environment.

RIPPLING AND SPINE WAVES

What’s the Deal With Oversaturated

Books?

Sometimes a comic becomes oversaturated—either from

improper humidification, storage in damp conditions,

or accidental water exposure. Oversaturation causes

the paper fibers to swell unevenly, creating rippling

across the cover and pages, often most visible along

the spine as spine waves. These defects make the book

look warped and unstable, and if not corrected properly,

they can return even after pressing. For all cold pressing,

make sure you are using aluminum, galvanized, or stainless-steel

plates to prevent rust from forming. Rust will appear

on the book and your plates when using normal cold rolled

steel plates.

Remove Oversaturation Permanently

1. Controlled Oversaturation (12–24 hours)

“Fight fire with fire.” Place the comic back into a

humidity tank with a gallon of boiled water for 12–24

hours. This step may sound counterintuitive, but the

goal is to re-soften the paper fibers evenly throughout

the book. By bringing the book to a uniformly pliable

state, you “reset” the paper, making it easier to reshape.

2. Cold Press (48 hours)

Transfer the oversaturated book directly into the press

machine and press without heat for 2 full days. Cold

pressing allows the fibers to slowly flatten under pressure

while excess moisture dissipates gradually. Because

no heat is applied, the fibers are not “sealed” too

soon—this gives them time to relax and bond back into

a flat, permanent position.

3. Final Humidity Tank (1 hour)

After the cold press, return the book to the humidity

tank for a short 1-hour session. This re-introduces

a mild level of flexibility into the fibers, preparing

the comic for the final press.

4. Normal Heat Press (24 hours)

Perform a standard heated press and afterwards leave

the book in the press machine for 24 hours before removing.

This final step locks the flatness into place, sealing

the fibers and ensuring the rippling and spine waves

do not return.

DENTS AND CREASES

Tack iron and ball bearing are to be used if a regular

pressing didn't work properly. Try a regular press first.

If you still aren't satisfied with your results, they

the "Ball Bearing and Tack" Method featured

in this video: https://youtu.be/Bd5WpGTjiIU

USING HUMIDITY

TANKS

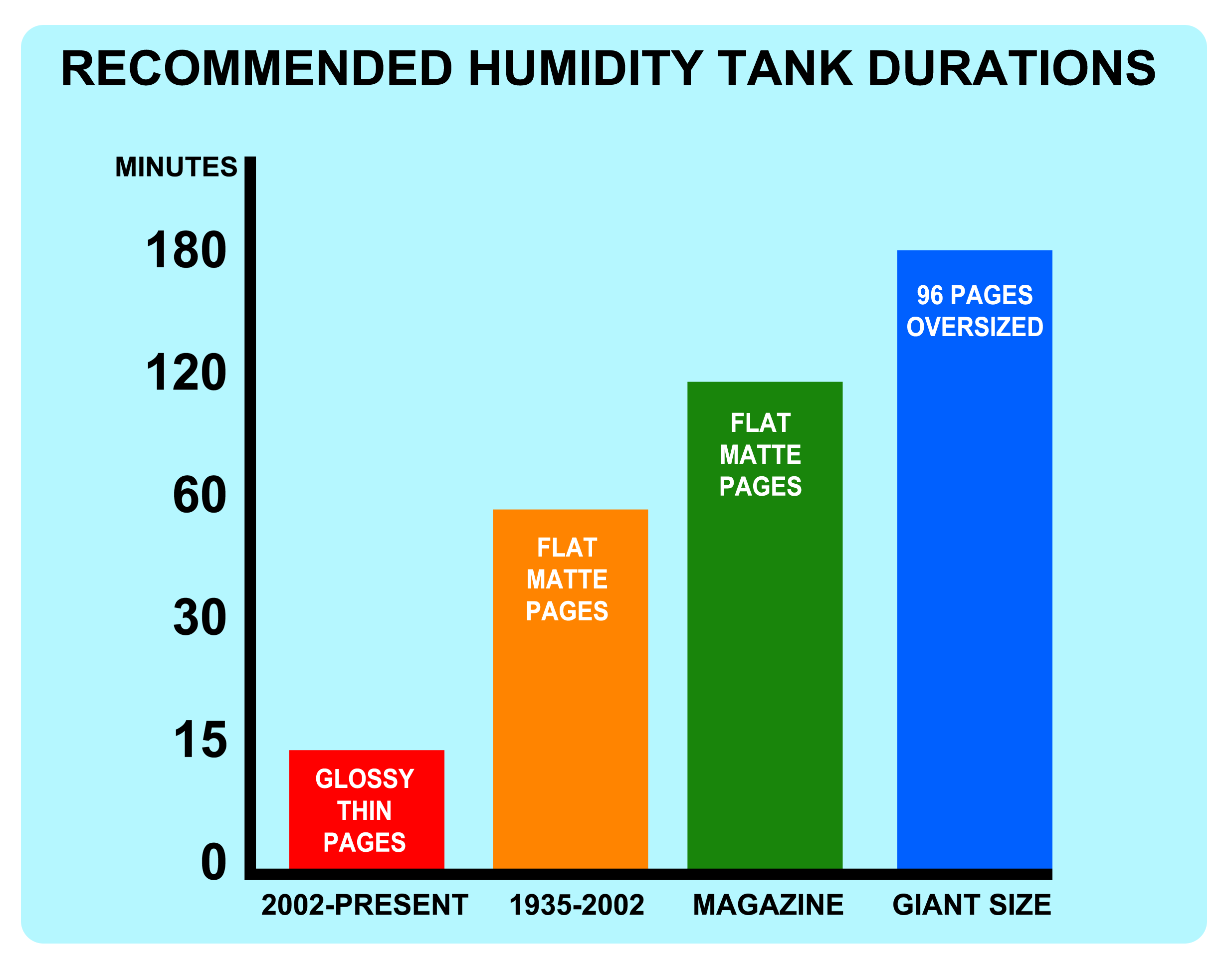

It’s quick and easy to assemble your very own humidity

tank (some call it a humidity chamber) from home. Durations

vary based on the type of paper stock and thickness.

For Modern Age magazines and giant-sized comic books

with glossy thin pages, the duration is cut in half

by 50%. Follow these simple instructions to introduce

controlled humidification to comic books:

1. Gather your supplies: 40 qt storage

bin, hygrometer, paper towels, four 20oz cups, two chip

clips, magazine sized backer boards + bags, a 16x10

dish drying rack, and latex gloves.

2. Boil a gallon of water on the stove.

Boiled water is a crucial component for durations.

3. Place the four spacers at each corner

of storage bin. Use plastic cups or PVC couplings.

4. Pour boiled water directly inside bottom

of the storage bin. There should be 1” to 2”

of water level from the bottom of tank. Smaller tanks

should use less than a gallon of water.

5. Place 16x10 platform directly on

top of the four spacers. The idea is to elevate the

platform above the water level, keeping the comic book

safely away from direct contact with water.

6. Place two assembled magazine-sized comic

bags + backer boards on platform. If you choose

to open a comic book, place the bag+boards side-by-side.

Keep centerfolds facing up. Do not flatten. You may

gently stack up to four books, separated by paper towels.

7. Place one assembled magazine-sized comic

bag + backer board on platform if you choose

to keep a comic book in a closed position. You may stack

up to four books, separated by assembled magazine-sized

comic bag + backer boards.

8. Place a final assembled bag + board on top

of book(s).

9. Place a layer of paper towels on

book(s). This is the water droplet protection from lid.

10. Place storage bin lid on top.

11. Place two plastic 3” chip clips

on outer rim of lid and storage bin wall. This creates

an airtight seal.

12. Place a heavy 10 lb object on lid such

as a gallon of water to keep downward pressure on lid.

Most comic books should be left in humidity tank from

30 minutes to 1 hour . Comic books with thin glossy

paper stock should be left no longer than 15-30 min.

TACK IRONS

Tack irons are a valuable tool for dent removal and

spine work. Tack irons can warp covers and pages if

set too hot. 160-180F is the safe temperature rage in

most cases. If your iron's lowest setting is still too

hot, make sure to use extra sheets of copy paper and

an included cloth sock over your iron to prevent scorching.

Keep the dial down to a #2 or a #3 for most work. Take

note which side is F and C for temperatures. Smooth,

fast, circular and steady motions with a tack iron is

safe. Constant heat applied on the same spot for 3-5

minutes or longer can damage the paper.

Tack Iron:

https://www.kaptainmyke.com/products/tackiron

C-NOTCH METHOD

When a comic book features staples that are 1/8"

too far inside the spine you will need to perform the

"C-Notch" Method to properly press. Instructional

video discussing the "C-Notch Method" when

pressing comic books with staples placed too far on

the inside of spine: https://bit.ly/3gMaZuy

COCKLING AND

RIPPLING

SRP paper holds water when pressing oversaturated books.

The water will collect on the opposite side of book

away from the heat platen. This water will remain trapped

between SRP paper and cover, causing ripples or cockles.

Press rippled covers with no SRP paper: Try using only

Backer Board, Cardstock Paper, and 1 sheet of 20 lb

copy paper on the outside of both covers when pressing

book between 2 steel plates. Cold press only,

using no heat for 2 days. On the 3rd day, remove

book from press machine. Press book normally now using

the humidity tank and a heat cycle. On day 4, the book

will be pressed flat with no ripples or cockling.

STAIN REMOVAL

Stain removal is not recommended if you are new to pressing.

Stick to the basics as you learn and continue to grow

your comic pressing hobby skills. Even experienced pressers

should tread lightly with this topic. Removing tanning

and foxing from a Golden Age or Silver Age book is not

easy. It requires days or even weeks using a very slow

process with a very steady hand. There is great risk

to destroying the book, the gloss layer of covers, and

lowering the overall value of book. We have developed

a set of methods to make this easier and safer on comic

books. There is still a lot that can go wrong if you

aren't experienced with our exclusive methods. The Heat

Overlay Press (HOP) Method and Blue Light LED (BLED)

Method is intended for experiened pressers. Our methods

are recommended for use only 2 or 3 times on an individual

book.

If you continue attempting stain removal methods you

can go too far on a book and damage it permanently or

get flagged for restoration.

BE PATIENT ⏳

Stop removing books too soon - they cause wavy warped

covers and wavy interior pages. 24 hours for all books

- except modern age glossy interior pages 2002-Present;

they can be removed and flipped after 2-4 hours. If

you want to press books faster and at a faster rate,

considering buying a second or a third press machine.

Pressing books take time and great care to achieve superior

results.

TIME OUT! ⏰

The clam shell and swivel press machines have a timer

maximum setting of 999 seconds, or 16 minutes. If you

need to press a book for 20 minutes, simply set the

press machine timer to 10 minutes. When the timer beeps,

simply switch off the machine and immediately turn it

back on for another 10 minutes. You do not need to open

and close the machine to reset timer.

EXPERIMENTATION

Experimentation is encouraged. One idea might work,

others not so much. Share your successes and pitfalls.

We all have been there. No judgement.

TAG! YOU'RE

IT!

Click here for topic hashtags: https://bit.ly/3qhvIJs.

You can also tag any member of the moderating team for

assistance. Do not be afraid to post or share your experiences.

Ask questions, we do not mind! We typically do not answer

with just "see the announcements" or "just

use the search". I am the type of person who will

search and tag you to help out. I don't mind.

OFF-TOPIC

If you wish to post off-topic posts or share your latest

pickups of the weekend, this is fine too. This is allowed.

THE DANGERS OF BAD PRESSING

http://bit.ly/2QVbgQY

is worth a read every once in a while to remind yourself

of what can happen if you aren't careful or feel rushed.

I'M NOT GETTING

THE SAME RESULTS!

Everything we do is all about "adapting to your

local environment". Try lowering the heat by 5

degrees. Comics are like people. We like to be comfortable.

The ideal conditions for pressing comics in your pressing

room and storage room for comics are 40%-50%

humidity and 70F-75F degrees.

These conditions can vary throughout the year as the

seasons change. Different heating and air conditioner

systems in homes and apartments can change these conditions

as well.

Here are some examples of adapting

to your local environment: